Woven metamaterials inspired by baskets for stiff, resilient robots

Able to undergo repeated compressions without losing their shape, woven materials could form robots, exoskeletons, car parts, architectural components and more.

Able to undergo repeated compressions without losing their shape, woven materials could form robots, exoskeletons, car parts, architectural components and more.

Experts

Doctoral Student of Civil and Environmental Engineering at the University of Michigan

Drawing on the prehistoric art of basketweaving, engineers at the University of Michigan found that woven materials return to their original shape after repeated cycles of strong compression, while continuous sheets of the same material permanently deform.

The modular platform to assemble woven corners presented in Physical Review Research could be used in any application where both resilience and stiffness are essential including soft robotics, car parts and architectural components.

After lead author Guowei Wayne Tu, a doctoral student of civil and environmental engineering at U-M, came across an article that dated woven baskets to around 7500 BCE, the researchers wondered if the ancient craft persists today for reasons beyond geometry and aesthetics.

Video description:

Text on screen:

“We knew weaving is an effective way of creating 3D shapes from ribbons like reed and bark, but we suspected there must also be underlying mechanical advantages,” said Evgueni Filipov, an associate professor of civil and environmental engineering and mechanical engineering at U-M and corresponding author of the study.

The study unearthed those mechanical advantages: high stiffness for load-bearing and resilience for long-term use.

“I’m very excited about harnessing the benefits of ancient basket weaving for modern 21st century engineering applications,” added Filipov. “For instance, lightweight woven materials for robotics would also help humans stay safer in case of human-robot collisions.”

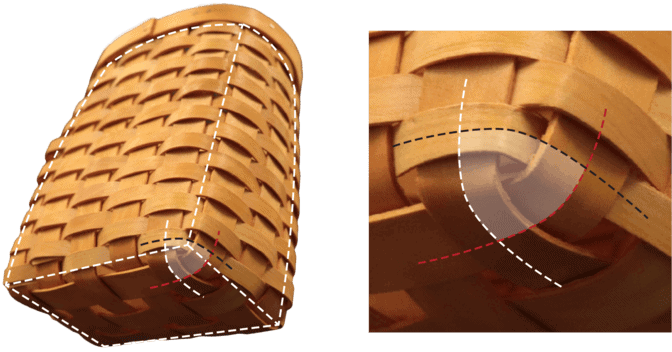

To test mechanical properties, the research team assembled structures by weaving together Mylar polyester ribbons, about the width of a pinky finger and the thickness of two sheets of copy paper, arranged perpendicularly to one another. They formed this 2D weave into a 3D metamaterial—meaning a synthetic composite material with a structure that creates physical properties not found in natural materials.

“While modern metamaterials are often designed for electromagnetic, optical or acoustic properties, people have been making mechanical metamaterials through weaving and other structural approaches for millenia,” said Tu.

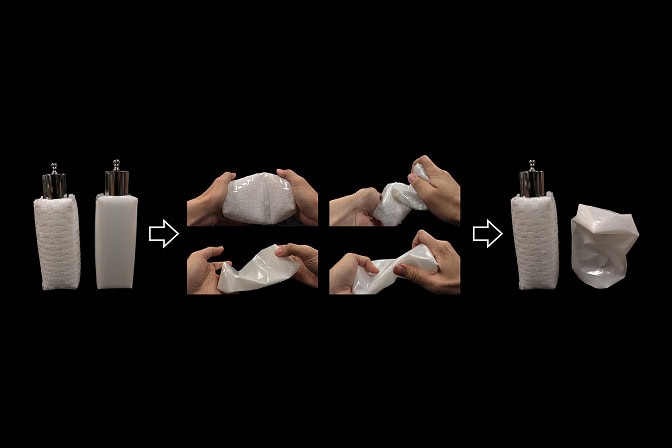

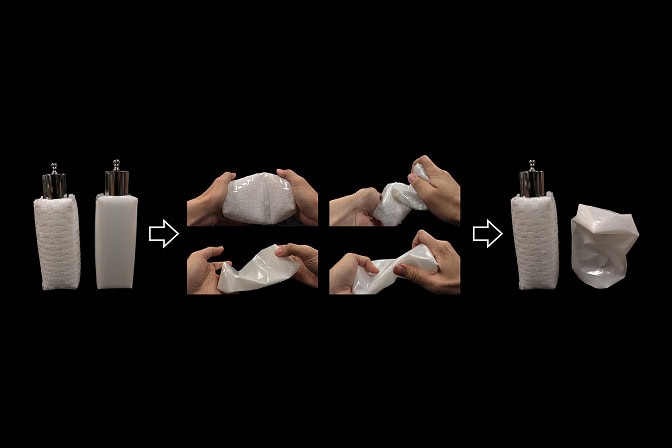

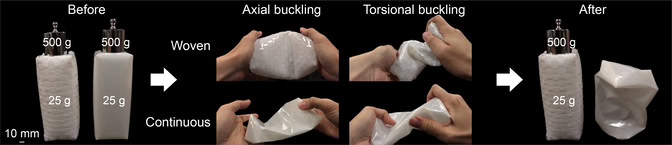

The structures used four different corner arrangements that brought together three, four, five and six planes. For comparison, the team assembled the same structures with continuous, unwoven Mylar. They then tested both types by progressively crushing them.

One pair of rectangular boxes standing 17 cm tall, returned to their original shape after being compressed by one centimeter. When compressed more, the continuous structure was permanently damaged while the woven structure was unchanged even after being compressed by 14 cm, to less than 20% of its original height.

High resolution 3D scans identified points on the continuous structure where concentrated stress caused the material to buckle and deform. The woven structure instead redistributes the stress across a wider area, preventing permanent damage.

Next, the research team investigated stiffness, measured by how much force is needed to compress structures from the top or bend them with a push on the side. They tested all four corner structures against continuous structures of the same Myler polyester. Across all experiments, woven materials were 70% as stiff as their continuous counterparts—disproving the misconception that woven systems are inherently flexible.

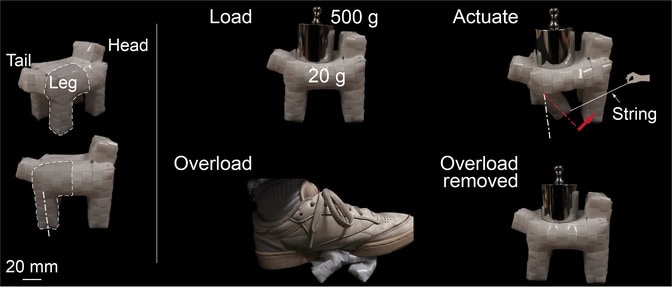

When testing more complex configurations, an L-shaped structure meant to resemble a robot arm supported 80 times its weight vertically—like holding a heavy bag at waist-level—and easily flexed upward, as a human arm would. A woven robot prototype with four legs that the researchers refer to as a dog held 25 times its weight and could still move its legs to walk. When overloaded, the woven dog robot returned to its original shape, able to hold the same weight again.

“With these few fundamental corner-shaped modules, we can design and easily fabricate woven surfaces and structural systems that have complex spatial geometries and are both stiff and resilient. There is just so much more potential for how we could use these corner-based woven structures for future engineering design,” said Tu.

As one such application, the researchers designed a concept for a woven exoskeleton that adapts stiffness for different parts of the human body—allowing movement while providing reusable shock absorption.

“Going forward, we want to integrate active electronic materials into these woven structures so they can be ‘smart’ systems that can sense the external environment and morph their shapes in response to different application scenarios,” said Filipov.

The research was funded in part by the US Air Force Office of Scientific Research (FA9550-22-1-0321).