A dual ion beam tests new steel under fusion energy-producing conditions

Researchers establish long-term helium trapping and swelling by titanium-carbide nanoparticles in a novel RAFM steel.

Researchers establish long-term helium trapping and swelling by titanium-carbide nanoparticles in a novel RAFM steel.

Experts

Doctoral Graduate of Nuclear Engineering and Radiological Sciences at the University of Michigan

A new class of advanced steels needs more fine-tuning before use in system components for fusion energy—a more sustainable alternative to fission that combines two light atoms rather than splitting one heavy atom. The alloy, a type of reduced activation ferritic/martensitic or RAFM steel, contains billions of nanoscale particles of titanium carbide meant to absorb radiation and trap helium produced by fusion within a single component.

When subjected to radiation damage and helium concentrations representative of fusion, the titanium-carbide precipitates initially helped trap helium but later dissolved under high damage levels. After dissolving, the alloy swelled as it was no longer able to disperse and trap helium, which could compromise fusion energy system components.

The first-of-its-kind systematic investigation led by University of Michigan engineers was published in Acta Materialia and the Journal of Nuclear Materials in a series of three papers.

“These results represent some of the highest fidelity results on radiation tolerance of fusion-relevant steels and will guide alloy development and refinement of radiation effects models for years to come,” said Kevin Field, a professor of nuclear engineering and radiological sciences and U-M and senior author of the studies.

Thus far, large-scale fusion systems have only been demonstrated in a handful of state-of-the-art national labs worldwide, including Lawrence Livermore National Laboratory in California. While fusion energy has garnered a great deal of interest, the technology is not yet ready for small-scale power plants.

Over 90 nuclear fission reactors currently operate in the US to provide a stable source of carbon-free energy, but researchers are looking to fusion energy as a more sustainable alternative. While fission typically relies on finite uranium resources, fusion could operate using hydrogen isotopes harvested from plentiful sources such as seawater.

Fusion energy also comes with increased safety benefits as it produces helium and short-lived radioactive waste that are easier to dispose of than long-lived radioactive waste from fission. Further, if a fusion energy system fails, the reaction simply extinguishes without the risk of a nuclear meltdown.

The drawback is that fusion energy systems must reach 100 million degrees Celsius—far hotter than the surface of the Sun—at the core of the reaction and allow other components such as those that use RAFM steel to reach up to 600 °C.

In addition to radiation and extreme heat, the neutrons generated from a fusion reaction can interact with materials and create helium within them. In high concentrations, helium can cause materials within the system to swell and warp. Developing a material able to withstand these extreme conditions is a critical step towards building a capacity for the clean energy source.

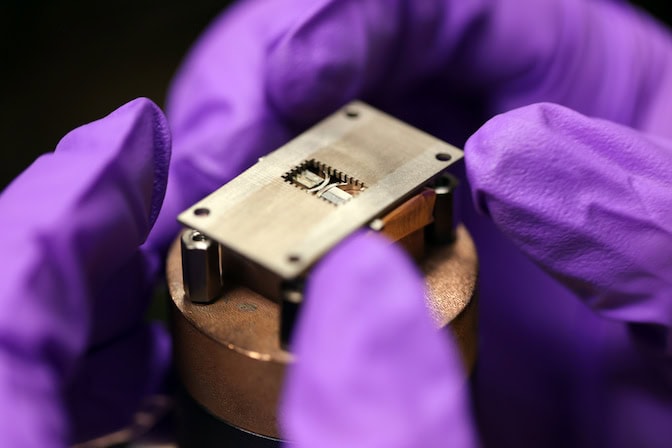

Up to this point, most experiments have only been able to test material’s radiation or helium resistance in isolation. In a more comprehensive approach, the researchers used a particle accelerator to simultaneously bombard steel samples with one iron ion beam—which inflicts radiation damage—and one helium ion beam, more accurately simulating fusion energy conditions.

Researchers can finely adjust radiation damage levels (one to 100 displacements per atom, or dpa), helium concentrations (10 to 25 atomic parts per million produced per dpa) and temperatures (from 300 to 600 °C) to better understand dose-dependent material behaviors.

“The level of control and detail in these experiments brings us significantly closer to simulating in-reactor conditions. This capability is essential as we push forward in discovering and optimizing materials to enable the future deployment of nuclear fusion power,” said T.M. Kelsy Green, a doctoral graduate of nuclear engineering and radiological sciences at U-M, current senior materials engineer at Antares and lead author of the three studies.

Specifically, the research team tested a new class of iron-chromium steel (Fe-Cr9) called castable nanostructured alloy #9, or CNA9 for short, a new generation of RAFM alloy engineered by the Oak Ridge National Laboratory fusion materials team that can hold a high density of titanium-carbide precipitates.

After exposure to the dual ion beams, samples were closely examined using state-of-the-art electron microscopy to characterize titanium-carbide precipitates and helium bubbles on the nanoscale.

The titanium-carbide particles trapped some helium as bubbles on their surface, with the highest success around 500 °C. Despite the partial success, the helium not captured formed bubbles in the bulk steel, causing the alloy to expand by 2% at the highest radiation levels.

Further, titanium-carbide precipitates showed some stability at higher temperatures (500-600 °C) and lower radiation levels (less than 15 dpa), but completely dissolved at higher damage levels (50 to 100 dpa) regardless of temperature. Results suggest the current alloy design would reduce radiation-resistance properties early in the fusion reactor’s operational lifetime.

“The results on the high radiation doses (>15 dpa) were surprising as we expected at the highest temperatures evaluated that the titanium-carbide precipitates would still be stable, but clearly this was not the case,” said Field.

Moving forward, the researchers suggest adjusting the steel by increasing the density of titanium-carbide precipitates by 1,000 times to more effectively prevent swelling and performing more ion beam tests at different rates to better simulate fusion energy environments.

“The preferential binding between TiC nanoprecipitates and helium atoms observed in this series of studies highlights the beneficial role of TiC in the newly developed CNA steels. Furthermore, the dissolution of TiC precipitates under high irradiation doses provides valuable guidance for future development efforts, emphasizing the need for more stable TiC precipitates in CNA steel design,” said Ying Yang, a research staff member at Oak Ridge National Laboratory and contributing author of the studies.

The experimental work was funded by the U.S. Department of Energy Fusion Energy Sciences program (DOE-FOA-0002173). The research was in part supported by Los Alamos National Laboratory (XXPV) and the US Department of Energy (DE-AC05-00OR22725).

Materials were studied at the Michigan Ion Beam Laboratory and the Michigan Center for Materials Characterization with the work performed by the NOME lab.