AI tool helps optimize antibody medicines

Machine learning points out why antibodies fail to stay on target, binding to molecules that aren’t markers of disease—and suggests better designs.

Machine learning points out why antibodies fail to stay on target, binding to molecules that aren’t markers of disease—and suggests better designs.

Antibody treatments may be able to activate the immune system to fight diseases like Parkinson’s, Alzheimer’s, and colorectal cancer, but they are less effective when they bind with themselves and other molecules that aren’t markers of disease. Now, new machine-learning algorithms can highlight problem areas in antibodies that make them prone to binding non-target molecules.

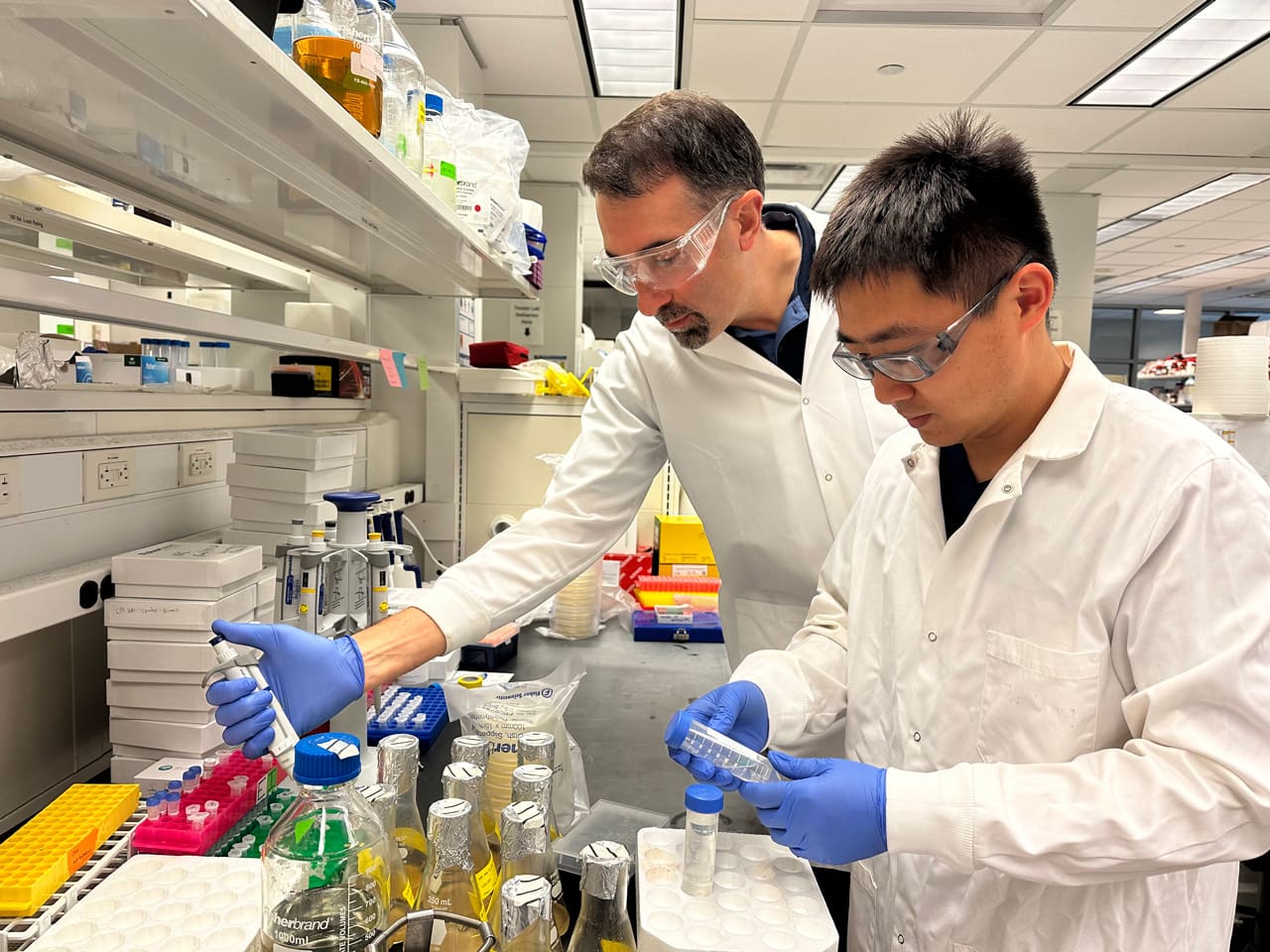

“We can use the models to pinpoint the positions in antibodies that are causing trouble and change those positions to correct the problem without causing new ones,” said Peter Tessier, the Albert M. Mattocks Professor of Pharmaceutical Sciences, Chemical Engineering, and Biomedical Engineering at the University of Michigan and corresponding author of the study in Nature Biomedical Engineering.

“The models are useful because they can be used on existing antibodies, brand new antibodies in development, and even antibodies that haven’t been made yet,” Tessier added.

Antibodies fight disease by binding specific molecules called antigens on disease-causing agents—such as the spike protein on the virus that causes COVID-19. Once bound, the antibody either directly inactivates the harmful viruses or cells or signals the body’s immune cells to do so.

Unfortunately, antibodies designed to bind their specific antigens very strongly and quickly can also bind non-antigen molecules, which removes the antibodies before they target a disease. Such antibodies are also prone to binding with other antibodies of the same type and, in the process, form thick solutions that don’t flow easily through the needles that deliver antibody drugs.

“The ideal antibody should do three things at once: bind tightly to what they’re supposed to, repel each other and ignore other things in the body,” Tessier said.

An antibody that doesn’t check all three boxes is unlikely to become a successful drug, but many clinical-stage antibodies can’t. In their new study, Tessier’s team measured the activity of 80 clinical-stage antibodies in the lab and found that 75% of the antibodies interacted with the wrong molecules, to one another, or both.

Changing the amino acids that comprise an antibody, and in turn the antibody’s 3D structure, could prevent antibodies from misbehaving because an antibody’s structure determines what it can bind. But, some changes could cause more problems than they fix, and the average antibody has hundreds of different amino acid positions that could be changed.

“Exploring all the changes for a single antibody takes about two workdays with our models, which is substantially shorter compared to experimentally measuring each modified antibody—which would take months, at best,” said Emily Makowski, a recent PhD graduate in pharmaceutical sciences fand the study’s first author.

The team’s models, which are trained on the experimental data they collected from clinical-stage antibodies, can identify how to change antibodies so they check all three of those boxes with 78% to 88% accuracy. This narrows down the number of antibody changes that chemical and biomedical engineers need to manufacture and test in the lab.

“Machine learning is key for accelerating drug development,” said Tiexin Wang, a doctoral student in chemical engineering and study co-author.

Biotech companies are already beginning to recognize machine-learning’s potential to optimize the next-generation of therapeutic antibodies.

“Some companies have developed antibodies that they are really excited about because they have a desired biological activity, but they know they are going to have problems when they try to use these antibodies as drugs,” said Tessier. “That’s where we come in and show them the specific spots in their antibodies that need to be fixed, and we are already helping out some companies do this.”

The research was funded by the Biomolecular Interaction Technology Center, the National Institutes of Health, the National Science Foundation and the Albert M. Mattocks Chair and was conducted in collaboration with the Biointerfaces Institute and EpiVax, Inc.

The University of Michigan and Sanofi have filed a patent application for the experimental method that provided the data used to train the algorithm.

Tessier has received honoraria for invited presentations on this research from GlaxoSmithKline, Bristol Myers Squibb, Janssen and Genentech.