Grad student’s ventilator design sparks conversations with doctors and engineers

Affordable proof-of-concept device automates the manual squeezing required by bag valve masks.

Affordable proof-of-concept device automates the manual squeezing required by bag valve masks.

Written by Shannon Danforth

A university of Michigan Engineering grad student has designed and prototyped a simple ventilator using common medical supplies. Although he’s stuck in his room, he hopes his posted instructions can serve as a template for those in the medical community.

An abundance of ventilator designs have appeared online in response to hospital shortages during the COVID-19 pandemic. Mechanical Engineering Ph.D. student Dan Bruder noticed that most require laser-cut or 3D-printed parts, making the designs impossible to construct without expensive tools. Dan consulted with his partner Mariama Runcie, M.D. to learn about the type of equipment available in most hospitals. He used this information to develop a simple ventilator prototype that plugs into hospital infrastructure, requiring less than $150 worth in parts.

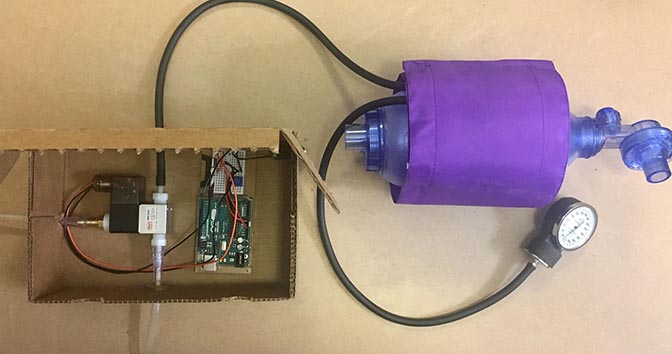

Positive pressure ventilation can be provided to patients by manually squeezing a handheld device called a bag valve mask (BVM). Because these devices need a human to squeeze the bag at regular breathing intervals, they cannot be used for extended periods of time. Dan’s design automates the required squeezing motion by wrapping a blood pressure cuff around the BVM. The ventilator would utilize compressed air and vacuum outlets, available in most hospitals, to inflate and deflate the blood pressure cuff. Dan programmed an Arduino microcontroller, a simple and inexpensive computer processor popular with roboticists, to direct the flow of air from these outlets.

“What I’ve built is really just a proof of concept. Medical professionals would still need to check its safety and its efficacy before using it,” Dan said, emphasizing that the design is not ready for hospital use. “My hope is that by publishing detailed instructions of how I built it, others in the maker or medical community will be able to recreate and improve upon the concept.”

Dan has been in contact with two doctors at the University of Texas Medical Branch who have developed and tested a similar design in a hospital setting. He offered his instructions to support their work.

“Since they have the knowledge and resources to actually evaluate their design in a clinical setting, I wanted to aid their efforts in any way possible,” Dan said.

The posted design has already led to iterations by other engineers. A team of undergraduate senior Mechanical Engineering students at Columbia University have proposed expanding Dan’s design for the Columbia DIY Ventilator Challenge. The team’s proposed ventilator introduces three changes: an alternative to using compressed air and vacuum outlets, a screen to report pressure values, and an alarm system for safety measures.

“We were glad to see that Dan’s design had no custom parts, and he had posted a video of it running already. We knew we could build on that,” said Millen Anand, team lead. “Now that our design is also posted online, we’ll see who can take this further, even if it’s not us.”