Renewable grid: Recovering electricity from heat storage hits 44% efficiency

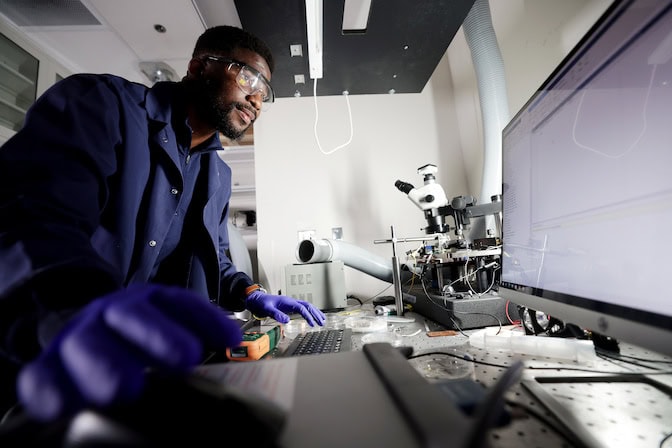

Thermophotovoltaics developed at U-M can recover significantly more energy stored in heat batteries.

Thermophotovoltaics developed at U-M can recover significantly more energy stored in heat batteries.

Experts

Peter A. Franken Distinguished University Professor of Engineering

Paul G. Goebel Professor of Engineering

Professor of Electrical Engineering and Computer Science

Professor of Material Science and Engineering

Closing in on the theoretical maximum efficiency, devices for turning heat into electricity are edging closer to being practical for use on the grid, according to University of Michigan research.

Heat batteries could store intermittent renewable energy during peak production hours, relying on a thermal version of solar cells to convert it into electricity later.

“As we include higher fractions of renewables on the grid to reach decarbonization goals, we need lower costs and longer durations of energy storage as the energy generated by solar and wind does not match when the energy is used,” Andrej Lenert, U-M associate professor of chemical engineering and corresponding author of the study recently published in Joule.

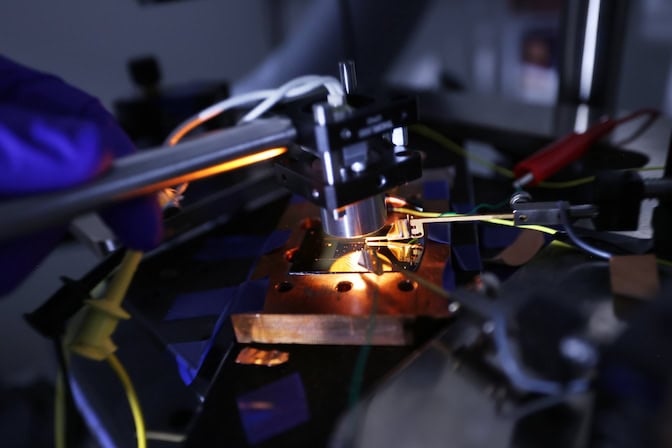

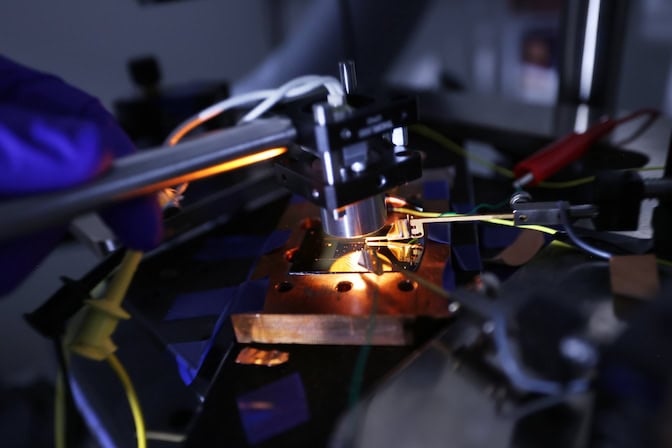

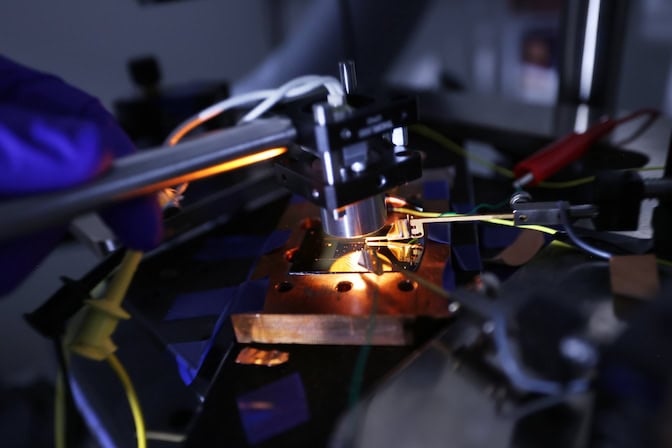

Thermophotovoltaic cells work similarly to photovoltaic cells, commonly known as solar cells. Both convert electromagnetic radiation into electricity, but thermophotovoltaics use the lower energy infrared photons rather than the higher energy photons of visible light.

The team reports that their new device has a power conversion efficiency of 44% at 1435°C, within the target range for existing high-temperature energy storage (1200°C-1600°C). It surpasses the 37% achieved by previous designs within this range of temperatures.

“It’s a form of battery, but one that’s very passive. You don’t have to mine lithium as you do with electrochemical cells, which means you don’t have to compete with the electric vehicle market. Unlike pumped water for hydroelectric energy storage, you can put it anywhere and don’t need a water source nearby,” said Stephen Forrest, the Peter A. Franken Distinguished University Professor of Electrical Engineering at U-M and contributing author of the study.

In a heat battery, thermophotovoltaics would surround a block of heated material at a temperature of at least 1000°C. It might reach that temperature by passing electricity from a wind or solar farm through a resistor or by absorbing excess heat from solar thermal energy or steel, glass or concrete production.

“Essentially, using electricity to heat something up is a very simple and inexpensive method to store energy relative to lithium ion batteries. It gives you access to many different materials to use as a storage medium for thermal batteries,” Lenert said.

The heated storage material radiates thermal photons with a range of energies. At 1435°C, about 20-30% of those have enough energy to generate electricity in the team’s thermophotovoltaic cells. The key to this study was optimizing the semiconductor material, which captures the photons, to broaden its preferred photon energies while aligning with the dominant energies produced by the heat source.

But the heat source also produces photons above and below the energies that the semiconductor can convert to electricity. Without careful engineering, those would be lost.

To solve this problem, the researchers built a thin layer of air into the thermophotovoltaic cell just beyond the semiconductor and added a gold reflector beyond the air gap—a structure they call an air bridge. This cavity helped trap photons with the right energies so that they entered the semiconductor and sent the rest back into the heat storage material, where the energy had another chance to be re-emitted as a photon the semiconductor could capture.

“Unlike solar cells, thermophotovoltaic cells can recuperate or recycle photons that are not useful,” said Bosun Roy-Layinde, U-M doctoral student of chemical engineering and first author of the study.

A recent study found stacking two air bridges improves the design, increasing both the range of photons converted to electricity and the useful temperature range for heat batteries.

“We’re not yet at the efficiency limit of this technology. I am confident that we will get higher than 44% and be pushing 50% in the not-too-distant future,” said Forrest.

The team has applied for patent protection with the assistance of U-M Innovation Partnerships and is seeking partners to bring the technology to market.

This research is based upon work supported by the National Science Foundation (grant numbers 2018572 and 2144662) and the Army Research Office (grant number W911-NF-17-0312).

Forrest is also the Paul G. Goebel Professor of Engineering and professor of electrical engineering and computer science, materials science and engineering, and physics.