Preventing infection: Nano-crumpled coating kills 99% of bacteria

Mimicking cicada wings, the stretchable material could offer a low-cost solution for patients with medical implants.

Mimicking cicada wings, the stretchable material could offer a low-cost solution for patients with medical implants.

In work that could dramatically reduce infection and promote healing in patients with medical implants like artificial joints or pacemakers, a new nanofabricated antibacterial coating developed at the University of Michigan relies on stretchable patterns of sharp peaks and valleys.

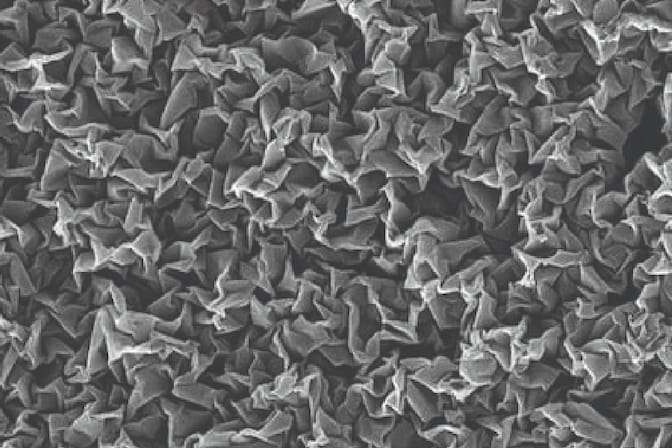

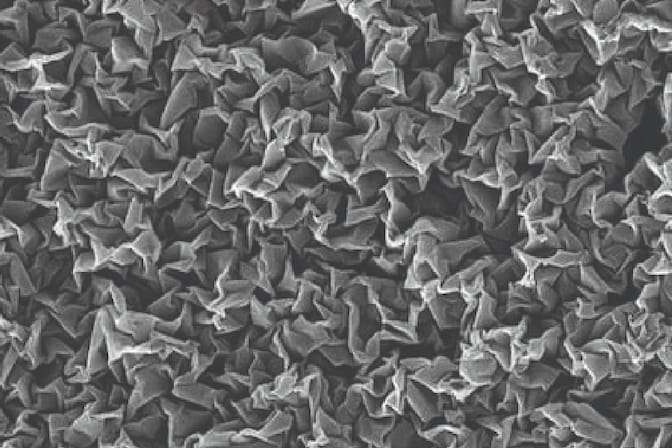

The approach is inspired by nano-scale topographies such as those on the wings of cicadas, the researchers wrote in a paper published in Advanced Materials Interfaces in 2023.

Michigan Engineering is advancing

critical technologies for a healthier world

The researchers developed the coating by layering flexible sheets of MXene, an ultrathin ceramic material with emerging uses in medicine, onto PDMS, a material commonly used in biomedical devices. In the process, the MXene forms crumpled peaks that kill bacteria when they try to adhere. Stretching the coating releases the debris.

“Unlike other antibacterial methods that release substances to kill bacteria, our approach involves shaping the MXene surface in a specific way,” said Jouha Min, assistant professor of chemical engineering.

“This breakthrough holds great potential in revolutionizing the field of biomaterials and implantable devices, offering a promising avenue to enhance patient safety and prevent infections.”

This is a summary of the article ‘A stretchable nano-crumpled material could help prevent infection in patients with medical implants’ by Taylor Schaffer.

Nicole Casal Moore

Communications & Public Engagement Director