Testing batteries for safety and performance without opening them up

A new formula makes sense of the way batteries respond to different alternating current frequencies, revealing materials, structures, faults and more.

A new formula makes sense of the way batteries respond to different alternating current frequencies, revealing materials, structures, faults and more.

By Makenzie Schlessman

A formula that can draw important conclusions about a battery’s internal components and condition from the way alternating currents move through it has been developed by Michigan Engineering researchers. It could help researchers identify battery faults during operation and design safer batteries.

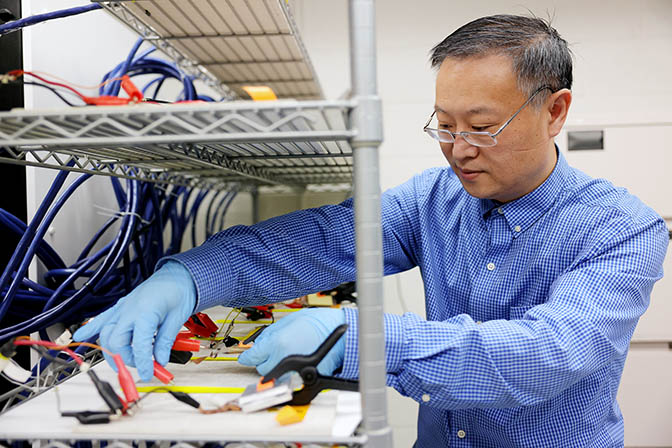

To ensure battery safety and performance, the industry needs effective techniques to monitor and diagnose a battery without tearing it apart. In a recent study that Applied Physics Letters highlighted as an editor’s pick, a team led by Wei Lu, a professor of mechanical engineering, reported a formula that can do this with measurements of impedance, an electrical property that compares output voltage to input current.

Until now, the relationship between impedance measurements and the internal state of the battery wasn’t known well enough to be broadly useful. In addition, the formula can be applied to other electronic and photonic devices.

The research team also includes first author Changyu Deng, a PhD student in mechanical engineering; Bogdan Epureanu, an Arthur F. Thurnau professor and professor of mechanical engineering; and Bogdan Popa, an associate professor of mechanical engineering.

We sat down with Lu to find out more.

Batteries are complicated systems made of many materials, including two electrodes that are two different materials, the membrane between them, and the electrolyte that carries ions from one electrode to the other during charging and discharging.

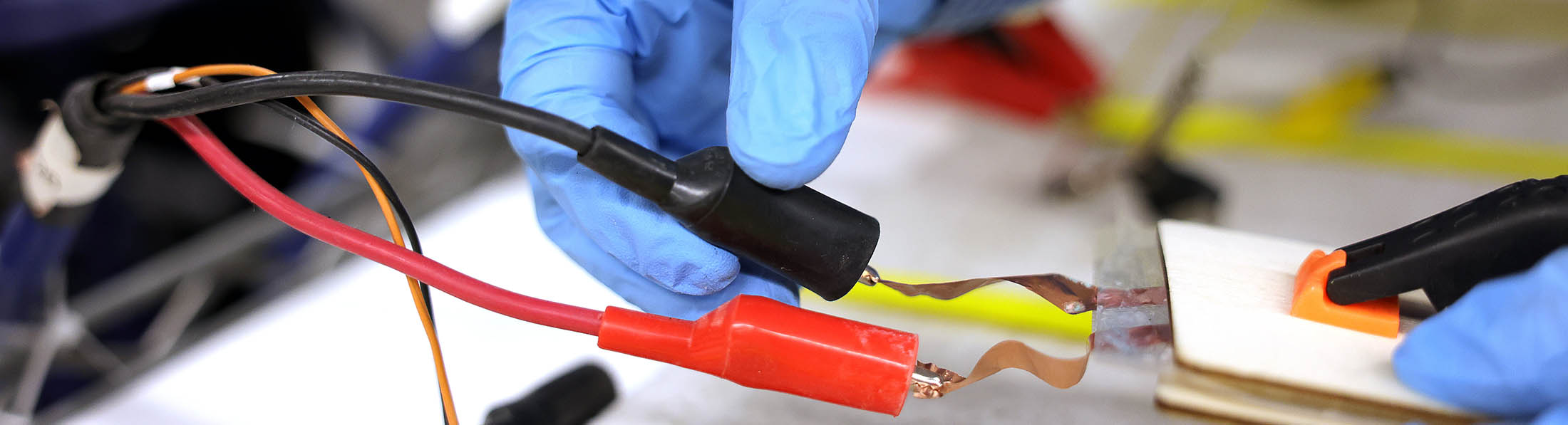

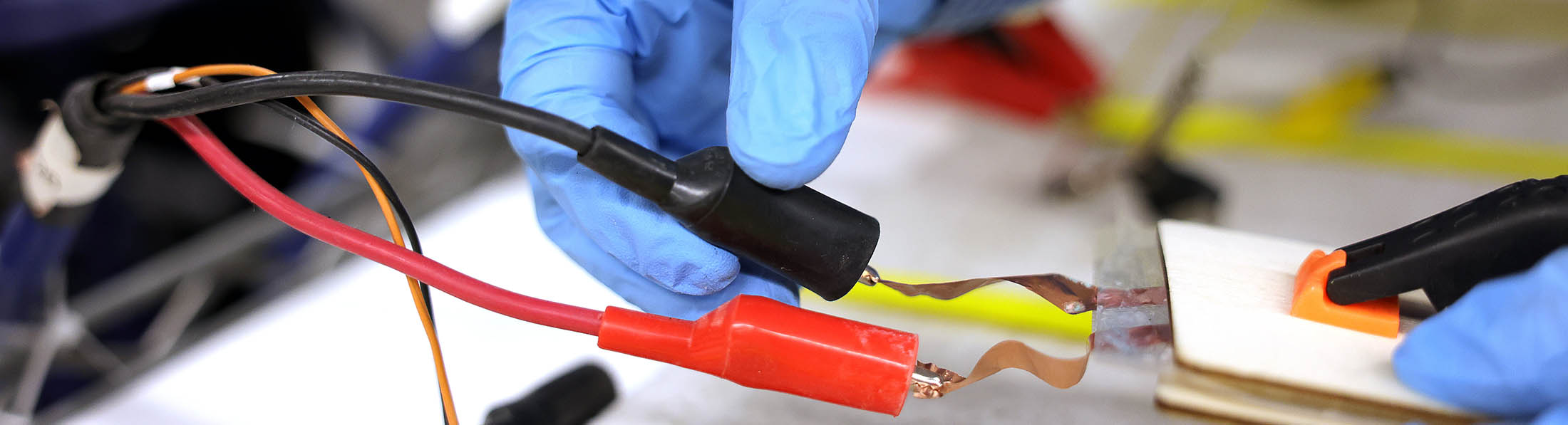

An important technique that researchers rely on when investigating batteries is applying an alternating current to probe the battery. This is the same kind of current you get from a wall plug, though much weaker, and the impedance changes depending on the frequency of the alternating current, or how quickly the current changes its flow directions.

One key measure is how impedance varies with frequency, or an impedance-frequency signature curve. We obtain it by sweeping the frequency from low to high, or millihertz to kilohertz frequencies. This curve is important because it is closely related to the internal material condition and state of the battery. It can be used to diagnose a battery for early fault warning or design better, safer batteries using the measured data. However, to make this work, it is necessary to build a relationship between the signature and the battery materials.

Therefore, we came up with our own formula to describe the relationship, and it works for any combination of battery materials. After measuring impedance at a few frequencies, the formula can predict impedance as a function of frequency for a wide range frequency range.

The formula serves as a tool to express material impedance from a few experimental data points. It simplifies the way to model how electricity moves through devices made with many materials, including batteries but also other electronic and photonic devices. Unlike earlier formulas, it doesn’t need to know the microstructure of the material in advance.

In battery development, the theory behind the formula helps researchers to understand the mechanisms that govern the performance of solid-state electrolytes, helping them to discover new and better electrolytes. Solid state electrolytes could make EV batteries safer, as liquid electrolytes are typically flammable.

The formula can also help guide which measurements a research team should make next, enabling teams to be more efficient as they design better solid electrolytes. By isolating the impedance of solid-state electrolytes, the formula can also help researchers to pinpoint the impedance features of other components of batteries, such as electrodes, and tune them for better designs.

Beyond the battery design stage, engineers can use the formula to help build concise and accurate models of the battery in the battery management system to deliver safer and more efficient control during charging and discharging.

We are going to incorporate this formula in our battery work. We have been working on explaining how solid-state electrolytes, a material for next-generation lithium batteries, transport ions. This is a key function, as the movement of ions within the battery drives electrons through the circuit to power devices. We plan to use this formula to understand and design solid state electrolytes with mixed materials, which can provide higher capacity and better safety.