An OLED for compact, lightweight night vision

Thinner than a human hair, the device amplifies and converts near infrared light into visible light with the potential for low power consumption and long battery life.

Thinner than a human hair, the device amplifies and converts near infrared light into visible light with the potential for low power consumption and long battery life.

Experts

Postdoctoral Research Fellow in Electrical and Computer Engineering

A new type of OLED (organic light emitting diode) could replace bulky night vision goggles with lightweight glasses, making them cheaper and more practical for prolonged use, according to University of Michigan researchers.

A memory effect in the OLEDs could also lead to computer vision systems that both sense and interpret incoming light signals and images.

Current night vision systems rely on image intensifiers that convert incoming near-infrared light into electrons, which then accelerate through a vacuum into a thin disc containing hundreds of tiny channels. As they pass through and collide with the channel walls, the electrons release thousands of additional electrons and go on to strike a phosphor screen, which converts them into visible light. The incoming light is amplified by 10,000 times in this process, allowing the wearer to see at night.

The newly developed OLED device also converts near infrared light into visible light and amplifies it more than 100 times, but without the weight, high voltage and cumbersome vacuum layer required for traditional image intensifiers. The researchers say much higher amplification is possible by optimizing the design of the device.

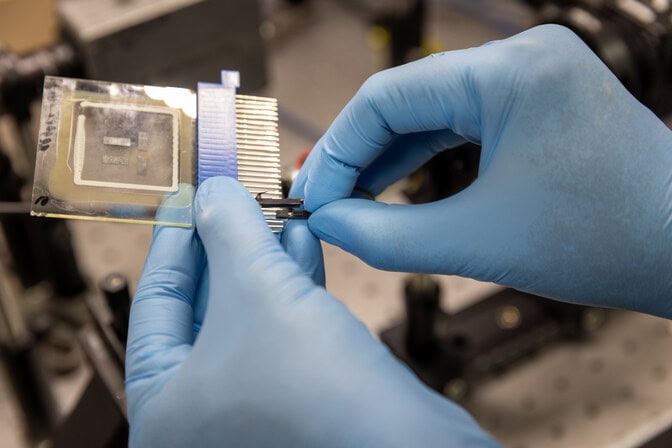

“One of the most attractive features of this new approach is that it amplifies light within a thin film stack that is less than a micron thick. That’s much thinner than a strand of hair, which is about 50 microns thick,” said Chris Giebink, U-M professor of electrical and computer engineering and physics and corresponding author of the study recently published in Nature Photonics.

Because the device operates at much lower voltage than a traditional image intensifier, it opens the door to significantly reducing power consumption and thereby extending battery life.

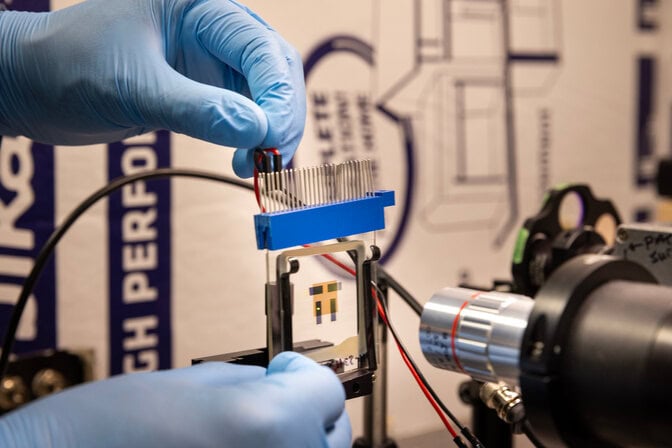

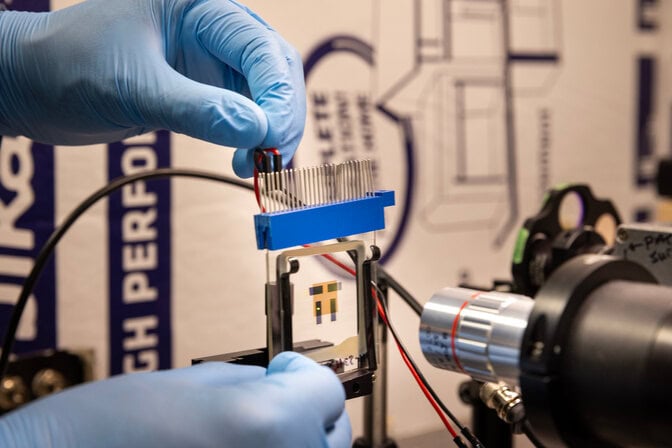

The device works by integrating a photon-absorbing layer, which converts infrared light into electrons, and a five-layer stack of OLEDs, where those electrons are converted into visible light photons. Ideally, five photons are produced for each electron that passes through the OLED stack.

Some of these photons are emitted out to the user’s eye, but others are reabsorbed back in the photon-absorbing layer, producing still more electrons that move through the OLED in a positive feedback cycle. This chain reaction greatly amplifies the amount of output light that results for a given amount of input light.

Previous OLEDs were able to convert near infrared light to visible light, but there was no gain, meaning one input photon yielded one output photon.

“This marks the first demonstration of high photon gain in a thin film device,” said Raju Lampande, U-M postdoctoral research fellow in electrical and computer engineering and lead author of the study.

The device also exhibits a sort of memory behavior that could have applications in computer vision. Known as hysteresis, its light output at a given moment depends on the intensity and duration of past input illumination.

“Normally when you illuminate an upconversion OLED, it starts outputting light and when you turn off the illumination, it stops outputting light. This device can get stuck on and remember things over time, which is unusual,” Giebink said.

Although the memory behavior introduces some challenges for night vision applications, it may create an opportunity for image processing that works more like the human visual system—where biological neurons pass signals on, or not, based on the timing and strength of incoming signals. The ability to remember past inputs could make these OLEDs a good candidate for the type of neuron-like connections that enable an input image to be interpreted and classified without having to process the data in a separate computing unit.

The researchers fabricated the device using “off the shelf” materials and methods that are already widely used in OLED manufacturing, which should improve both cost effectiveness and scalability for future applications of the technology.

The work was carried out in collaboration with OLEDWorks, a company that manufactures OLED lighting products, and RTX, an aerospace and defense contractor. The technology is patent-pending by OLEDWorks and Penn State University, where the study originated before Giebink moved to U-M. This research was funded by DARPA (Award No. HR0011-22-C-0053).