U-M’s space design and manufacturing draws second round of support from DARPA

Without the constraints of building on Earth, engineers look to expand the capabilities of what space structures can do.

Without the constraints of building on Earth, engineers look to expand the capabilities of what space structures can do.

Engineers at the University of Michigan are redefining what man-made space structures can be and do, and their success in designing a solar array to be manufactured in space has U.S. defense officials supporting a new project designing an antenna.

The things we build and send into space are limited by the fact they’re built and tested on Earth. Anything made on the ground needs to be packaged up, stored aboard a rocket and shot beyond the atmosphere. It creates space and weight issues that restrict the size of structures we use in space research and exploration.

But we don’t have to do it that way. The weightlessness of space provides the possibility to build enormous structures, but they would have to be made there. The Defense Advanced Research Projects Agency (DARPA) has been funding researchers at U-M to help make it happen.

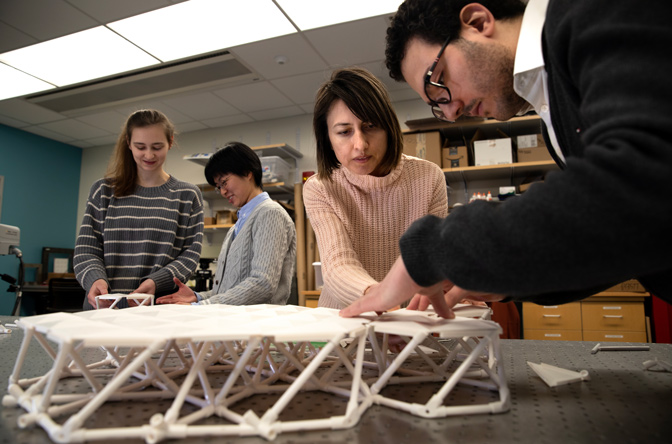

In 2021, DARPA provided $1.58 million to a team led by Serife Tol, a U-M assistant professor of mechanical engineering, to design a new modular solar array that can be 3D-printed in space. The project is part of the Novel Orbital Moon Manufacturing, Materials and Mass Efficient Design (NOM4D), and the U-M team’s work has been promising enough that DARPA has issued a second grant to continue the work.

This time, it’s a $1.3 million grant to design a new antenna that can be produced in space or on the moon. The goal is to create lightweight and highly precise structures based on advanced manufacturing technologies.

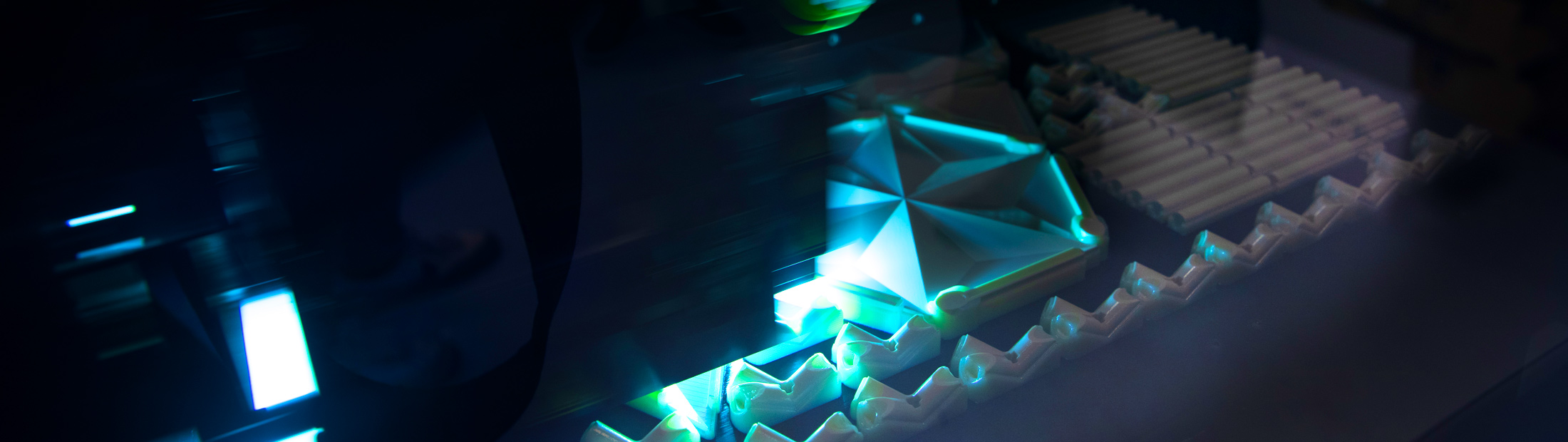

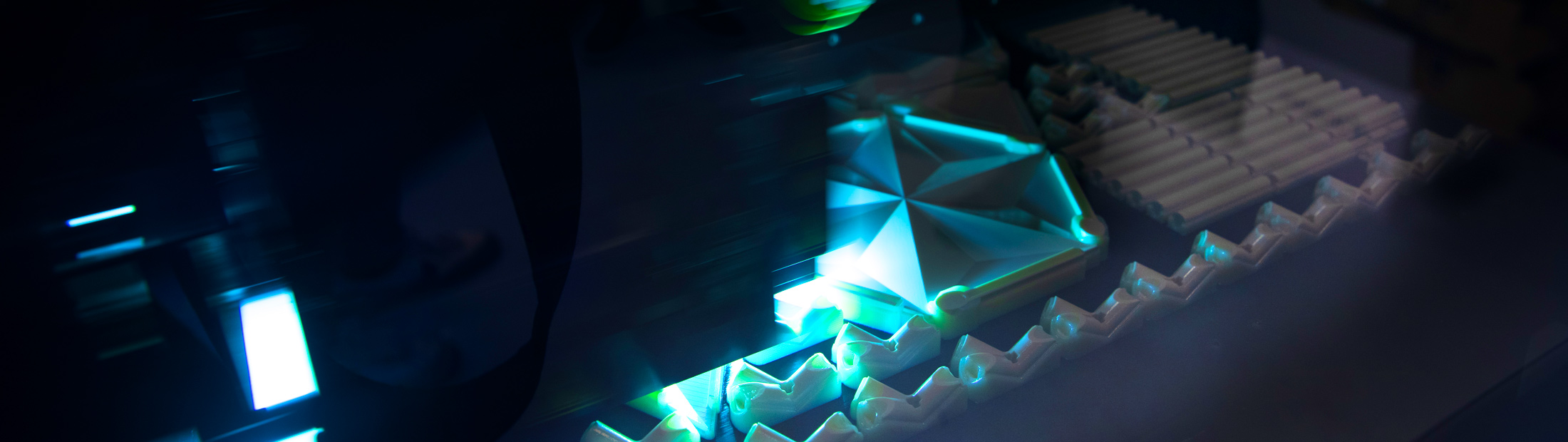

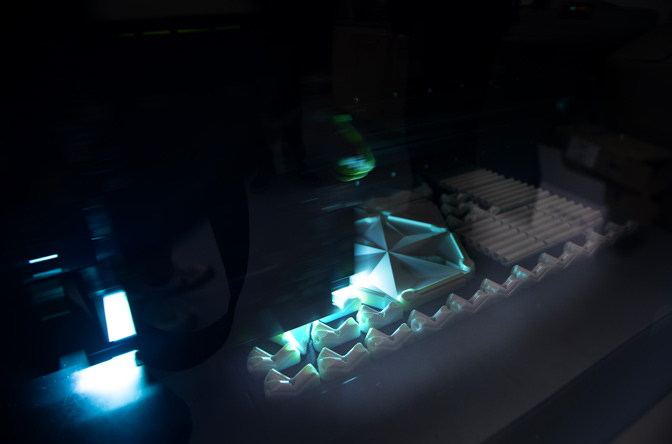

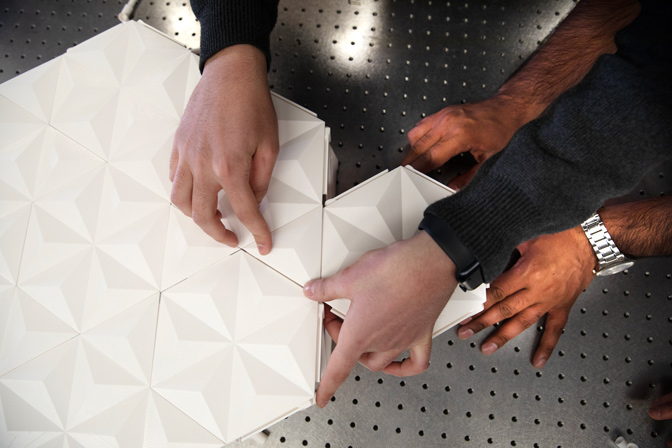

That includes techniques used to make metamaterials, which behave differently from natural materials. They are made of repeating—or periodic—structures and can be designed to create new mechanical properties and more.

For Tol, “on-orbit,” or “in-space” manufacturing opens up an off-world of design opportunities.

“We’re looking for novel designs, ones that aren’t limited to the constraints of space launches or deployability,” she said, as the team prepares for its second go-around with the NOM4D program. “Without those limits, we can explore creating structures that are much larger than those on Earth and enable drastic performance increases.

“To this end, we’re creating new space designs based on periodic architecture, the so-called metamaterials.”

3D printers can crank out the small building blocks of these larger creations. That allowed the U-M team to successfully design its enormous solar array, which can perform far beyond what can be launched into space from Earth. Even so, current plans would send the raw materials to space, which is why mass efficiency—or the power production per unit mass—remains an important measure.

“Today we are limited in the size, both the mass and the volume, that we can launch from Earth,” said Andrew Detor, NOM4D’s program manager in a recent podcast. “The NOM4D program is really about fundamental materials and manufacturing technologies and enabling the construction of large structures in orbit. Things like solar farms, the more solar cells you can put out in terms of area, the more power you can harvest.”

The U-M team’s previous work on the array is proof.

“Compared to a state-of-the-art solar array producing 300 kilowatts of power, our team’s array is capable of producing 1 megawatt of power with higher mass efficiency and precision,” Tol said.

Expectations for the new antenna are equally optimistic.

The current standard for a mesh reflector antenna used for satellite communications is the Harris reflector, which is roughly 12 meters in diameter. U-M engineers are designing an antenna that will be more than 100 meters across.

The challenge lies in creating the support for that expanded surface area. A larger antenna requires more support in the form of ribs beneath its blanket-like surface to prevent the pillowing effect—deformations in the mesh surface that affect accuracy. However, this approach can significantly increase the mass of the structure, which is not desired.

“Because of the plethora of metamaterial designs that in-space manufacturing can produce using 3D printing, we will be able to address and solve several issues, such as pillowing, using our approach,” said Anthony Waas, the Richard A. Auhull Department Chair of Aerospace Engineering, and a member of the research team.

Following the success of the solar array, the team has progressed into the second of NOM4D’s three phases.

Efficiency targets were the focus in the first round, and increasing mass efficiency is at the heart of the second, to be demonstrated with the antenna project. The third round will involve demonstrating precision with infrared sensing.

“Assuming current space technology trends continue, in 10 to 20 years we expect to see advances that will enable DoD [Department of Defense] to take full advantage of the NOM4D-developed technologies and capabilities,” said Bill Carter, NOM4D’s founding program manager in DARPA’s Defense Sciences Office, when the program kicked off last year.

“This includes robotic manipulation sufficient to enable assembly of large structures from NOM4D-manufactured components, enhanced on-orbit mobility, and routine re-fueling of on-orbit assets,” he said. “We also anticipate several other advantages, including more affordable space access and launch costs in LEO [low-earth orbit], GEO [geosynchronous orbit], cislunar orbit [the space between Earth and the moon], and beyond.”