Unbreakable bonds

The properties of PFAS are so great that we have used these chemicals widely—so widely that now they contaminate our water, our air, our land and our bodies. What can we do about it? Engineers have some ideas, although it’s not going to be easy.

Written by:

Story by Jim Lynch, photos by Marcin Szczepanski

Questions began sneaking into Tammy Cooper’s head almost immediately—unwelcome, sometimes brutal questions piling up in her mind, creating a mountain of guilt.

What should I have known? When should I have known it? And what might I have done to my child because of it?

In the summer of 2018, those thoughts hit Cooper and other parents in the small city of Parchment, Mich., when they first learned that water from their home taps contained frightening levels of something called PFAS. For Cooper, it was akin to throwing gas on a fire.

She and her husband, David, had long harbored concerns about two-year-old daughter Jillian’s low body weight. The Coopers had moved to Parchment from nearby Kalamazoo when Jillian was just six months old, and Tammy had breastfed her daughter that whole time.

“I immediately thought, ‘Should I try to drink a bunch of bottled water?’” Tammy recalled. “‘Is there a way for me to flush out my system?’”

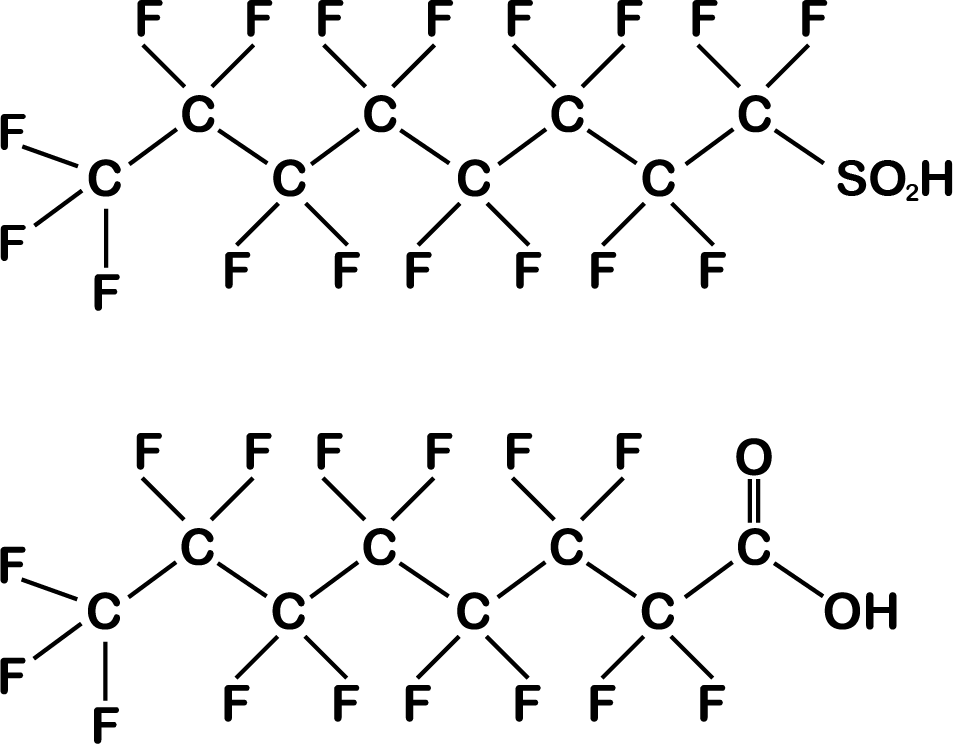

PFAS represents a group of more than 3,000 chemicals, two of the most widely used being Perfluorooctanoic Acid (PFOA) and Perfluorooctane Sulfonate (PFOS). Most share the common traits of collecting in our bodies and our environment, and being difficult to break down once they’re there.

In a way, the worst thing about PFAS may be the questions they raise: from the local immediacy of concerns like Cooper’s, to national and global questions about assessing and limiting further damage.

Officials in Belgium wonder how to deal with millions of cubic feet of contaminated soils found during a massive infrastructure project in Antwerp. In the Arctic, wildlife officials puzzle over how to protect polar bears from PFAS found in melting ice. And near former military bases across the United States, residents wonder who they can trust in dealing with the fallout from decades of PFAS dumping.

Underlying all of this, a central question looms large: How do we get rid of them safely?

I immediately thought ‘Is there a way for me to flush out my system?’”

Right now, we can’t. PFAS are typically handled by incinerating them or burying them in landfills. Incineration, however, doesn’t completely destroy the particles and may only spread them over a wider area. Landfills eventually leak into local groundwater.

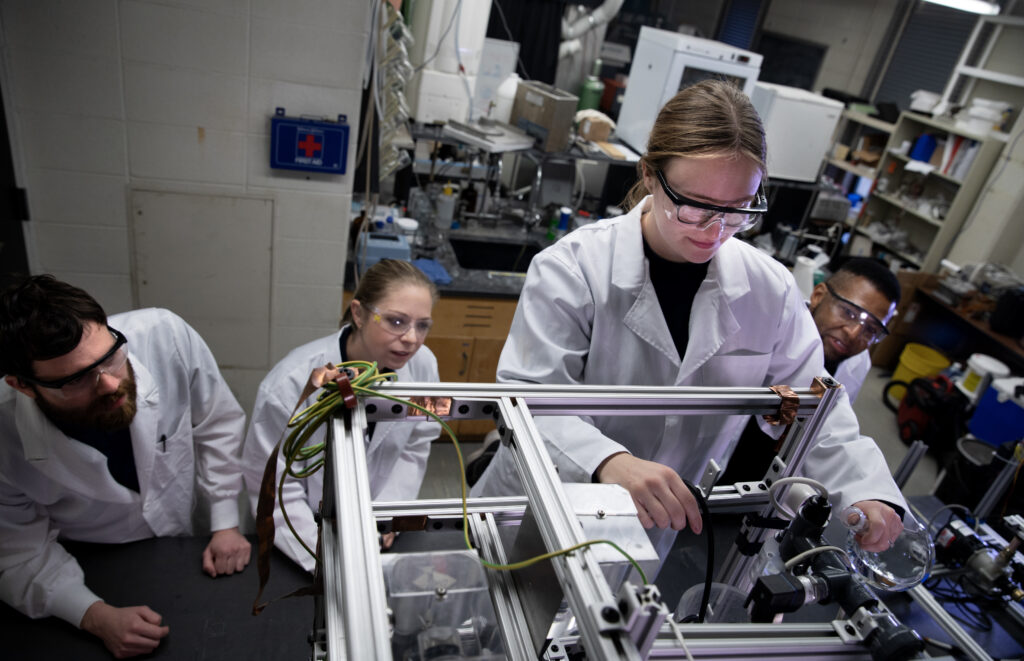

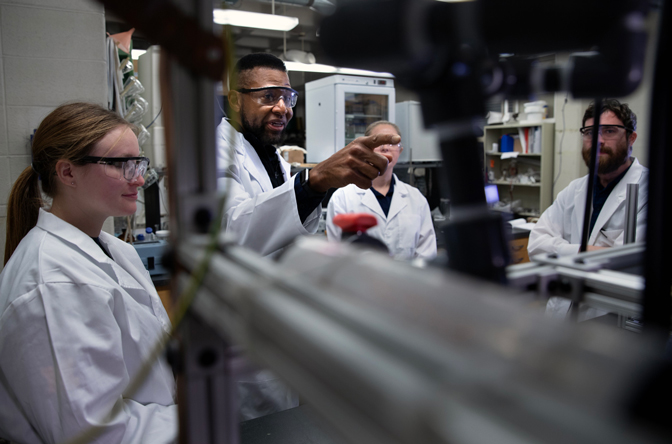

University of Michigan nuclear engineers are scaling up new technology that utilizes cold plasma to destroy PFAS in drinking water. Not move the chemicals, destroy them.

“The State of Michigan has some of the strictest standards for PFAS in drinking water,” said John Foster, a U-M professor of nuclear engineering as well as aerospace engineering. “Our cold plasma reactor has been able to treat water that meets those standards and beyond.”

The ability to break PFAS into harmless chemical components is a potential game-changer since PFAS are what we call “forever chemicals.” The chemical bonds are difficult to break down, allowing PFAS to linger in bodies, water and soils. And what we know about their impact in each of those areas seemingly gets worse all the time.

In June, the EPA announced PFAS chemicals in drinking water are more harmful than previously thought, presenting health risks even when consumed in small quantities.

As of now, the U.S. Centers for Disease Control and Prevention have linked exposure to PFAS chemicals to a range of health problems that include increased risk of kidney and testicular cancer; decreased vaccine response in children; increased risk of pre-eclampsia in pregnant women; small decreases in infant birth weights; and changes in liver enzymes.

In response to the growing understanding of health risks, new regulations of PFAS are under consideration. But no amount of heightened awareness or new regulatory action will address what’s already in our bodies and our environment.

Parchment’s contamination most likely originated from its industrial past, particularly the mills that gave it the name “The Paper City.” After toxic chemicals were discovered, Parchment tied into neighboring Kalamazoo’s water system, removing Parchment’s water safety as a concern for Cooper and other residents.

Contaminated property, however, remains. And, once again, the PFAS presence there is raising hard questions around what’s best to do with it, pushing some residents into different camps.

“We have people making offers for part of the mill property,” said Cooper, who channeled her early worry into a successful run for city council. “One of the arguments for selling is that there is no cleanup method we can rely on right now and we want to get the land back on the tax rolls.

“But you also have younger people saying, ‘Wait a minute, there are people who are working on this. If we wait, maybe 10 years down the road, we might have an opportunity to clean it up.’”

Ties that bind

The diagram above shows the heart of the problem—the chemical bonds that characterize chemicals in the PFAS family. The key is the inclusion of multiple fluorine atoms attached to an alkyl chain—an attachment strong enough to resist breaking down in the environment.

If you look closely, those fluorine molecules form a wall around the carbon, protecting from outside attacks. Conventional water treatment methods can’t crack that protective layer

“They are the strongest bonds that exist in chemistry,” said Terese M. Olson, a retired U-M associate professor of civil and environmental engineering, who has worked with Foster on cold plasma technology. “They take a lot of energy to break, but that’s what you have to do to make this compound less hazardous.”

What has helped spread PFAS to seemingly all parts of the globe are the incredible properties they impart. After their discovery and development in the mid-20th century, chemical companies found a host of products that could be improved through the use of PFAS—things your parents and grandparents never knew they couldn’t live without.

Need jackets that better repel water? Introducing Gore-Tex! Want furniture that will resist stains? Buy a chair or couch treated with Scotchgard! Tired of scrubbing food particles off your pots and pans? Try cookware coated with Teflon!

Amazement overran caution, and testing of the potential impact on human health and the environment was minimal. Wonder products continued to roll out, decade after decade. And despite what we know now, this continues. Some manufacturers are moving away from PFAS.

In December, global manufacturing giant 3M announced it would stop making PFAS chemicals and eliminate their use in product lines… by 2025.

Bond busting

To kill these PFAS chemicals, Foster and his team rely on something that’s very much like lightning in a bottle.

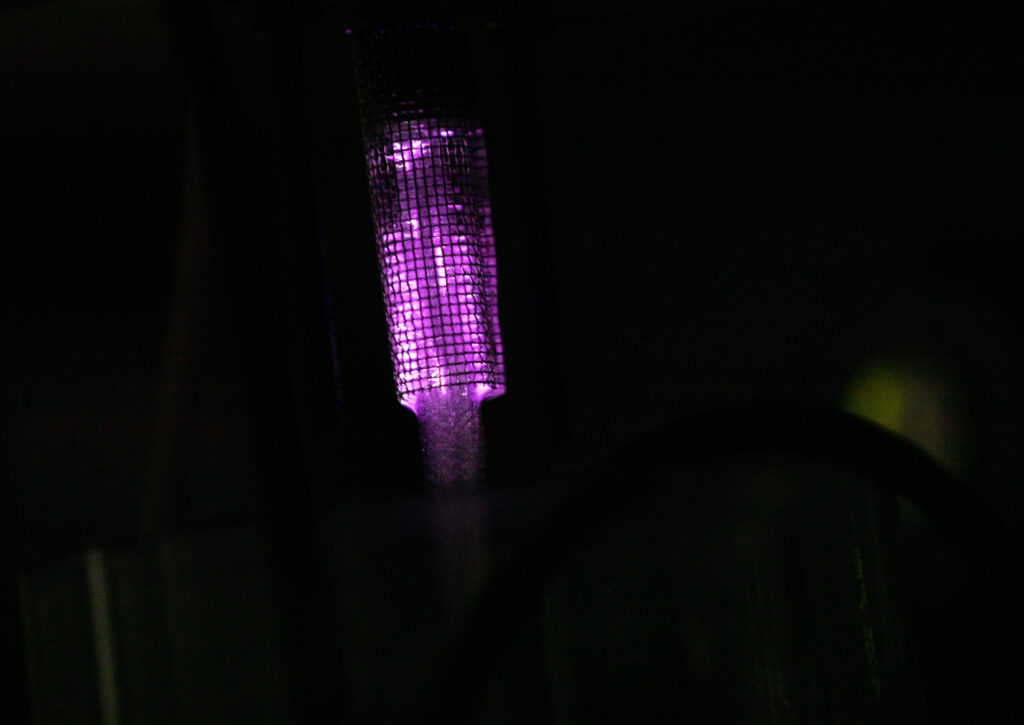

When you talk plasma, you’re talking ionized gas—the same thing you see with a lightning strike. Electrons and ions get separated, resulting in electrons flying around carrying a great deal of energy. It’s those “energetic electrons” hitting gas molecules that produce the light in lightning.

Most plasmas involve extremely high temperatures. Think of arc welders, which operate at around 6500 degrees F. Plasma at those temperatures is great for cutting metal, but try using it to treat water and that water would boil off immediately.

Cold plasmas are actually just room temperature. Fast, high-voltage pulses of electricity are applied to the air in the reactor, ionizing the gas there and creating energetic electrons. While the electrons are very hot, neutral atoms are not, keeping the overall temperature lower. When the electrons strike gas molecules, they break into electron and ion pairs, and that process repeats over and over.

“Those pulses of electricity essentially create a cloud of electricity that surrounds the water that’s being treated,” said Joseph Groele, a graduate student research assistant who has worked with Foster for several years.

Part of the trick is making the PFAS molecules available to the plasma. PFAS molecules tend to reside on water surfaces, so the U-M team introduces water into the reactor in streams, through something like a showerhead.

By using the streams, the contact area between the plasma and the water is increased. Access to more surface water means more PFAS are destroyed.

The electrons and plasma attach to PFAS molecules in the water, making those fluorinated bonds—normally so strong—unstable. Eventually, the protective fluorine atoms are popped off from the chain, leading to the entire chain’s decomposition and resulting in harmless amounts of carbon dioxide and fluorine gas.

Water must be funneled through this process several times and then it’s ready for human use.

“We looked at several reactor types and settled on one that seemed to be very effective at PFAS removal,” Foster said. “And that was one designed with high throughput in mind. We’ve recently developed an architecture for it that allows us to scale up.”

In February, the U.S. Department of Agriculture awarded a $175,000 grant to Fourth State, the company founded by Foster, Groele, and Roxanne Walker, a graduate student research assistant, to do just that. Later this year, they will complete work on a cold plasma reactor capable of treating 40-50 gallons of water per minute.

It’s a plunge into a drastically different research area from where Foster started—his initial interest in cold plasma focused on using it to propel spacecraft. The shift seems prescient now, given the stakes involved in PFAS.

And few communities demonstrate those better than Oscoda, Mich.

“Where everything comes naturally”

When you’re home to weapons of war like the massive B-52 “Stratofortress” bomber, as well as the nuclear weapons they’re tasked with carrying, you train for safety—over and over again, week after week. You prepare for worst-case scenarios involving fuel, planes or munitions. It’s fire training designed to save lives.

Over several decades, Wurtsmith Air Force base in Oscoda regularly conducted exercises that utilized a fire suppressant called Aqueous Film Forming Foam (AFFF). Designed to extinguish flammable liquid fires, the foam incorporated PFAS to reduce surface tension and allow the product to spread.

The foam was allowed to seep into the ground on and around the base. Wells on-site were eventually found to have high levels of PFAS, and the chemicals made their way into the local aquifer.

“They did everything wrong,” said Mark Henry, an environmental engineer and now a co-chair of the Wurtsmith Restoration Advisory Board.

Today, current and former residents of Oscoda—a city with the slogan “Where Everything Comes Naturally”—are still trying to determine the ramifications.

Public health

She didn’t know it at the time, but the first indication something might be wrong came to Cathy Wusterbarth at age 28. In the same calendar year, she was diagnosed with breast cancer and then rheumatoid arthritis.

Growing up, she and other kids spent endless hours at Oscoda’s Van Etten Lake. In her late teens, Wusterbarth worked summers there as a lifeguard.

“The beach there is located right near the end of the Wurtsmith runway,” said Wusterbarth, now 53. “These days, we see neighbors suffering from cancers. We don’t know what the rates are.

“We can’t directly link our exposure to the conditions in that area at the time, but it’s pretty suspect.”

Craig and Carrie Minor believe the link is beyond suspect, and that PFAS, “more likely than not,” was the cause of their greatest heartbreak.

The couple met at college in Virginia in 1982, and got engaged the day after their first date. (A good derby pie works wonders.) Jobs that allowed Craig to use his chemistry degree were sparse, so he enlisted in the United States Air Force.

After training as a B-52 pilot in Mississippi, he was assigned to Wurtsmith, and the Minors, now with a son, moved to a town just north of Oscoda. While living off-base, they welcomed a daughter who, like her brother, was generally healthy and happy.

The growing family would eventually move onto the base where the tap water came from nearby wells. When their third child, Mitchell, arrived, it did not take long to realize something was wrong.

“He wasn’t doing the same things developmentally as his brother and sister,” Carrie Minor said. “He wasn’t pushing up, wasn’t moving his head. He didn’t roll over.”

Doctors eventually diagnosed Mitchell with microcephaly, a condition where a baby’s brain fails to develop normally during pregnancy, resulting in a head that is smaller than expected. Those same doctors told the Minors that Mitchell would be lucky to live until his fifth birthday.

“He wasn’t verbal,” Carrie Minor said. “He never walked. He was tube-fed. But he brought real joy to our lives.” He passed away Jan. 25, 2020, at the age of 31, after a challenging, yet impactful life.

Both Carrie and Craig, now living in Ohio, have amassed a list of health issues over the years—far beyond what you’d expect for people their age—and they attribute those to their time living at Wurtsmith.

Craig worries over what has yet to be done to fix the groundwater once piped into their former home.

“The PFAS is in the ground and the Department of Defense has a responsibility there,” he said. “Now, they could play at ignorance in the past … but you know it’s in the ground now. It’s a poison and it’s flowing in the aquifer and it harms people. You have to do whatever you can to get that stuff out of there and get rid of it.”

The environment

Along with Van Etten Lake, it’s worth taking a look at what else borders the Wurtsmith property. To the south sits Clark’s Marsh, which connects to a nearby river.

That river is the Au Sable, one of the state’s most famous due to its world-class trout fishing further west. The spread of PFAS through sections of Iosco County has led to numerous restrictions on what fishermen and hunters can do with what they catch or kill in the area.

During firearm hunting season in November, the Michigan Department of Health and Human Services warned against eating deer taken in the 3-mile area surrounding Clark’s Marsh—the only area in the state with an advisory for deer.

“That’s a lot of state land, a lot of public land for people to hunt,” said Roger Byrne, who works at Wellman’s Bait & Tackle, just north of where the Au Sable River meets Lake Huron. “A lot of people who hunted there have shied away from it.”

A release issued at that time went even further, saying, “ … MDHHS continues to recommend that people not eat organs from any fish, deer, or other wild game in the state because many chemicals, including PFAS, can accumulate in the organs of wildlife.”

Fish contamination is a larger problem in Michigan, and PFOS, that common type in the PFAS family, are the major culprit. State officials currently test 800 to 1,000 fish per year to monitor PFAS levels. In cases where contamination is found, 85% of the time it’s due to PFOS.

In January, the nonprofit Environmental Working Group released a study suggesting that eating a single PFAS-contaminated fish from freshwater could provide the same exposure as drinking a month’s worth of contaminated water.

Swimming in streams, rivers and lakes with PFAS contamination is not currently considered a health risk. Yet MDHHS recommends avoiding PFAS foam that builds up along the shores of lakes and rivers that are contaminated, and suggests rinsing or showering after coming into contact with them.

“There is no scientific evidence of how PFAS moves through the skin,” the MDHHS website says. “However, MDHHS evaluation of how young children might get foam on them at the beach finds a health risk could exist from repeated, prolonged whole-body contact with foam.”

For people like Byrne invested in the health of Oscoda’s environment, the cloud of PFAS hangs over what should be a prosperous time. In recent years, the area fishery has exploded with a variety and abundance of fish—which should have out-of-town anglers flocking in.

“If you ask the locals, they’ll tell you they don’t mind. But the travelers still can’t get past what they’ve read,” he said. “A lot of that is from the way the advisories are worded. You can play in the water, but don’t touch the foam. You can swim around, but don’t eat the fish.”

Biting the bottom line

For a tourist town, none of this is good news. But reputation issues go beyond tourism.

In 2021, MLive reported how Oscoda Township was in line for loan assistance from the state to build much-needed housing that could help bring skilled workers to the area. But the targeted property sat above Oscoda’s tainted aquifer and the Michigan State Housing Development Authority “didn’t like the optics of building atop pollution.”

The deal fell through. And the article described a domino effect from the PFAS stigma.

“Hotel owners say it drives cancellations,” it read. “Realtors say it tanks housing deals. Residents worry about how it may impact their property values. Elected officials call it a time suck that’s raising utility and infrastructure costs.”

In a state where the tourism motto is “Pure Michigan,” these things add up to an uncomfortable situation. In 2021, outdoor recreation generated $10.8 billion in revenue and was responsible for 109,595 jobs. So there’s much at risk.

“The fact there is an additional threat to the wildlife—the game that people are going out to hunt and fish—is a threat to those industries, and how people think about hunting and fishing,” said Jennifer Hill, associate director of the National Wildlife Federation’s Great Lakes Regional Center, in an October interview with the Associated Press.

Michigan, as a whole, runs the risk of repeating what’s happened in Oscoda. Plot out PFAS contamination sites on a map of the U.S. and the state jumps out, thanks to more than 230 documented locations—more than anywhere else in the country.

It’s somewhat misleading. Yes, Michigan has its share of military bases and old industrial sites. But the truth is, Michigan has been looking for PFAS contamination more closely than most states.

The problem started to crystallize in 2017 when contamination was detected around the Wolverine World Wide Tannery near Rockford. Residents voiced concerns over waterproofing at the facility, a process that involved Scotchgard.

Water sampling at local homes soon showed those concerns were well-founded and state officials moved to create the Michigan PFAS Action Response Team (MPART) later that year.

“At that point, PFAS became a very, very real issue,” said Abigail Hendershott, MPART’s executive director. “We’ve gone from having, initially, some 20 sites we were aware of to, now, 233 sites.

“And we’re adding new sites every week.”

They come from a variety of sources, with landfills accounting for the largest number, followed by industrial sites, plating operations, airports and the military bases. All in a state that relies heavily on its groundwater.

“Michigan has very prolific aquifers with over 1.2 million drinking water wells across the state,” Hendershott said. “Roughly 25 percent of the state gets its water from non-municipal systems.”

When other states begin looking for PFAS contamination in the same way Michigan has, they are likely to find a costly situation. Military sites alone indicate a massive bill is on the way.

We’ve gone from 20 sites to 233 sites. And we’re adding new sites every week.”

Roughly 300 current and former military bases previously used AFFF for firefighting and training. The USAF estimated cleanup at Wurtsmith—just Wurtsmith—could cost as much as $250 million.

To limit further PFAS damage back in Michigan, the state’s Department of Environment, Great Lakes and Energy (EGLE) in 2020 enacted standards for seven PFAS compounds for both groundwater and drinking water. The allowable level for PFOS was set at 16 parts per trillion, while the level for PFOA was set at 8 parts per trillion, among the toughest standards in the nation. The federal standards for both were 70 parts per trillion.

But nothing is easy. In 2022, 3M successfully challenged part of the state’s regulations, and the full implementation of the new standards remains in legal limbo.

No single solution

While upcoming technologies like cold plasma offer a note of hope for killing PFAS, simply being able to do something is different than being able to do it efficiently and affordably.

“Wastewater treatment plants handle millions of gallons of water and waste products each day, which means that a PFAS treatment technology will need to be effective at large volumes in a rapid time period,” Hendershott said. “Most of these technologies are still in the bench stage or pilot stage. We need them to be ramped up in order to deal with large quantities.”

That will require companion technologies to build a larger, multifaceted treatment system just to reach a cold plasma reactor, according to Henry, the Wurtsmith Restoration Advisory Board co-chair.

“Simply getting contaminated water to (a collection) point for treatment is still a problem,” he said. “Pumping groundwater, there’s no part of that process that’s inexpensive. It is woefully inadequate.”

As an example, full remediation of the groundwater beneath Wurtsmith requires extraction wells located around nearly seven miles of border, plus support buildings and infrastructure. And decades of extraction running all day, every day will be needed to prevent contamination from spreading further.

Hendershott agreed, saying a combination of technologies, what she calls a “treatment train,” will be necessary to make the most of PFAS killing technologies.

Next-gen chemicals are already here

Foster is already looking beyond the current forever chemicals to what’s coming next—and it seems frustratingly familiar.

“Here’s the problem, they replace the current PFAS with a substitute chemical, where they change just a little bit of the PFAS compound,” he said. “So they have these new GenX chemicals to replace the PFAS, but they still fluorinate them.

“Those are still a contamination problem, but it’s just that they haven’t been around long enough to be recognized as such. And once they are recognized, the chemical companies will replace them again.”

One researcher, Foster noted, calls it “chemical whack-a-mole.”

So far, U-M’s cold plasma technology has demonstrated the ability to break down these new chemicals as well, since the compounds remain fluorinated. The chemical chains are shorter which, unlike traditional PFAS, means the chemicals will not reside naturally at the surface, but the reactor’s design forces the chemicals there.

PFAS and their chemical successors, however, represent a problem technology may not be able to solve.

Like cigarettes before them, PFAS products were released for consumption long before the public understood their potential impacts. The U.S. regulatory framework doesn’t require chemical companies to ensure the safety of their products or determine their long-term impacts before sending them to market.

“You can develop these wonder chemicals that make our lives easier, but no one conducts health studies before they’re introduced to the public for use,” Foster said. “Those studies are expensive and may take 20 years to complete, so companies view them as impractical.”

In a perfect world, this current reckoning with our PFAS past would lead to another hard question about our chemical future and the promise of amazing new products.

Is it worth the risk?