Treating PFAS water contamination with cold plasma

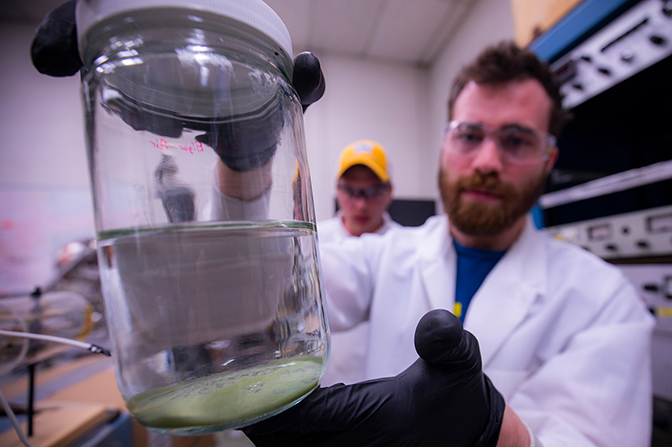

University of Michigan researchers are developing better plasma technology that can destroy PFAS compounds

University of Michigan researchers are developing better plasma technology that can destroy PFAS compounds

As the state of Michigan begins enforcing new limits on PFAS compounds in drinking water, the need is intensifying for efficient, cost-effective treatments to address these “forever chemicals.”

University of Michigan researchers are developing a scalable technique for destroying perfluorinated alkylated substances in water using cold plasma, or charged gas. While most mitigation strategies focus on removing PFAS, this approach goes a step further. It aims to actually break down the PFAS and convert them into something less hazardous.

A growing concern around the U.S., PFAS are considered a dangerous legacy from the nation’s industrial past. The engineered chemical compounds were first introduced 80 years ago and quickly found use in a variety of applications—fabric protectants, cleaning products, paints, fire-fighting foams, as well as non-stick coatings for kitchenware.

Roughly 5,000 different types exist today, and most of them share the ability to remain in the environment for extended periods of time. Known as forever chemicals, they can resist breaking down, posing threats to human health on multiple fronts. According to the U.S. Centers for Disease Control and Prevention, exposure may be linked to increased cancer risk as well as changes in liver enzymes, decreased vaccine response in children, increases in cholesterol and heightened risk of high blood pressure in pregnant women.

“One of the reasons PFAS are difficult to degrade is they contain so many carbon fluorine bonds,” explained Terese M. Olson, associate professor of civil and environmental engineering. “Those are the strongest bonds that exist in chemistry. They take a lot of energy to break, but that’s what you have to do to make this compound less hazardous.”

When mitigation strategies simply remove PFAS from water, the byproduct of concentrated PFAS needs to be disposed of somewhere. Usually it goes into landfills or gets incinerated and, over time, re-enters the water supply.

Olson is looking for a more permanent solution, one that could be scaled for use at water treatment plants. Her search led her to cold plasma.

Cold plasma is essentially an activated gas made of energetic electrons, which have virtually no mass and therefore very little heat content. Here’s how the researchers envision it could work: When the plasma comes in contact with contaminated water, the electrons attach to the PFAS molecule. This makes the carbon fluorine bonds unstable, causing the molecule to break down into its component parts. The result is a release of carbon dioxide and fluorine gas, in small quantities that do not pose a health risk.

“Essentially, you’d remove most of these building blocks of the PFAS molecule from the water almost atom by atom,” said John Foster, professor of nuclear engineering and radiological sciences and Olson’s partner on the project.

The fast-moving electrons would also physically bombard the PFAS molecules, breaking them up mechanically.

In preliminary laboratory tests on samples of water containing PFAS, the researchers have demonstrated that a substantial amount of the PFAS was destroyed in the plasma treatment process. Further testing is needed to optimize the process to eventually achieve the new regulatory limits for PFAS.

One of the challenges is creating a solution that could efficiently scale to treat large quantities of water. Plasma destruction is an energy-intensive process, so the more water that needs to be treated, the more expensive the treatment becomes. Olson is testing a preliminary step of concentrating the water, to remove the same amount of PFAS from a smaller volume of water.

“We expect that a concentration approach will provide a much more efficient process that enables PFAS destruction technologies such as plasma,” Olson said.

Olson and Foster’s ultimate goal is to scale this technology so that it can be used efficiently and affordably in water treatment plants or at industrial sites.

“I foresee ten years down the line that plasmas will become a bit more mainstream in water treatment, just like UV light is now almost standard in most wastewater plants,” said Foster. “I think plasmas will be essentially standard as a stage to polish the water to remove these contaminants of emerging concern.”