Harnessing ultrasonic waves to better monitor aging pipeline infrastructure

Phononics can address problems with signal attenuation.

Phononics can address problems with signal attenuation.

Pipelines that run beneath our feet, some as old as the cities they service, are often far past their intended lifespan and the need for replacing them looms as an expense most municipalities can’t afford.

The need for better monitoring of these aging lines is paramount, and the harnessing of ultrasonic waves—through phononics—may provide municipalities with a cost-efficient method of preventing breaks and addressing the most dangerous areas first.

Serife Tol, a University of Michigan assistant professor of mechanical engineering, is utilizing elastoacoustic waves that pass along pipelines to deliver a wealth of information infrastructure operators can use.

The UM team’s latest research results are available in Applied Physics Letters. Contributors include researchers from the University of Illinois at Chicago.

Phononics looks at elastic or acoustic waves and how they move through materials that are composed of repeating, or periodic, structures. These periodic materials include phononic crystals and metamaterials for applications such as isolating unwanted sounds and vibrations, or acoustic invisibility devices.

Artificially engineered periodic structures can be designed using elements such as rods, beams, plates or shells, all of which exhibit extraordinary dynamic properties not found in natural materials. Those properties determine how the elastic or acoustic waves travel.

Elastic waves propagating in a pipe can serve as a tool for detecting leaks, cracks, bends and more. Defects present in structures will disrupt the elastic or acoustic wave signatures—and that disruption can be detected by sensors mounted on the pipe surface. Analyzing the arrival times of waves in the receiver signal determines the location and type of defect present in the pipe wall. This type of guided wave testing is already widely used as a non-invasive structural health-monitoring technique.

Phononics is a new science that’s still being explored by researchers, and this is the first time we’re looking at it for sensing applications in pipelines. We’re demonstrating its effectiveness compared to current monitoring technologies such as ultrasonic guided waves.

Ultrasonic waves have proven to be cost-effective and easy to operate, partly because the pipeline itself serves as a wave guide. However, the method suffers because the waves amplitude get smaller and harder to detect during long-range inspections of pipelines.

This problem can be overcome with phased array technology, which focuses ultrasonic elastic waves and improves defect detection and localization. But the technology behind wave focusing requires active control through external devices and a database of wave characteristics specific to each pipeline.

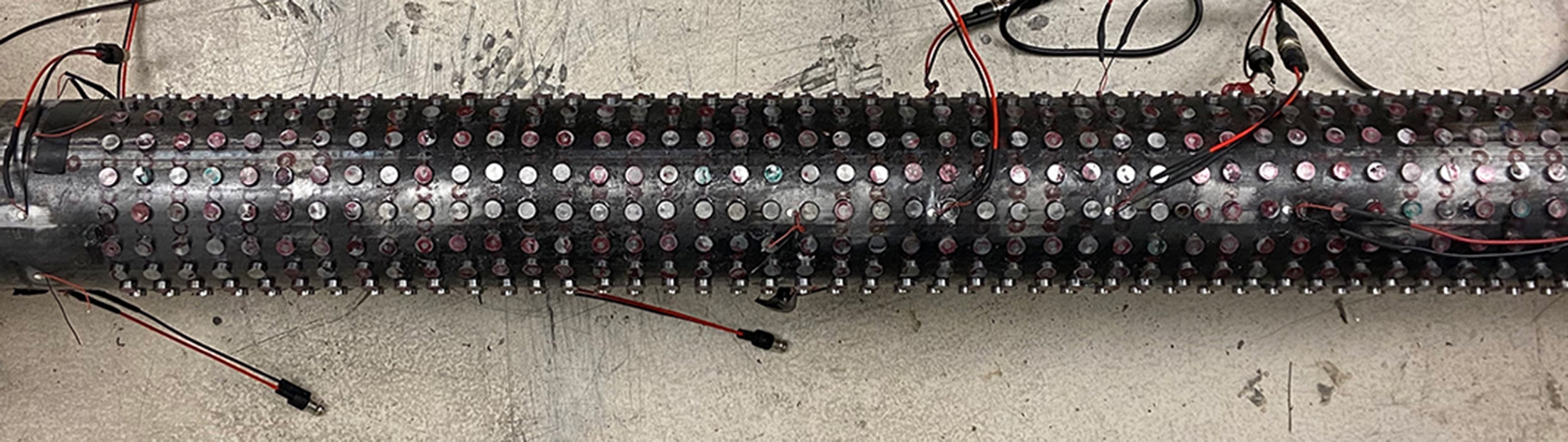

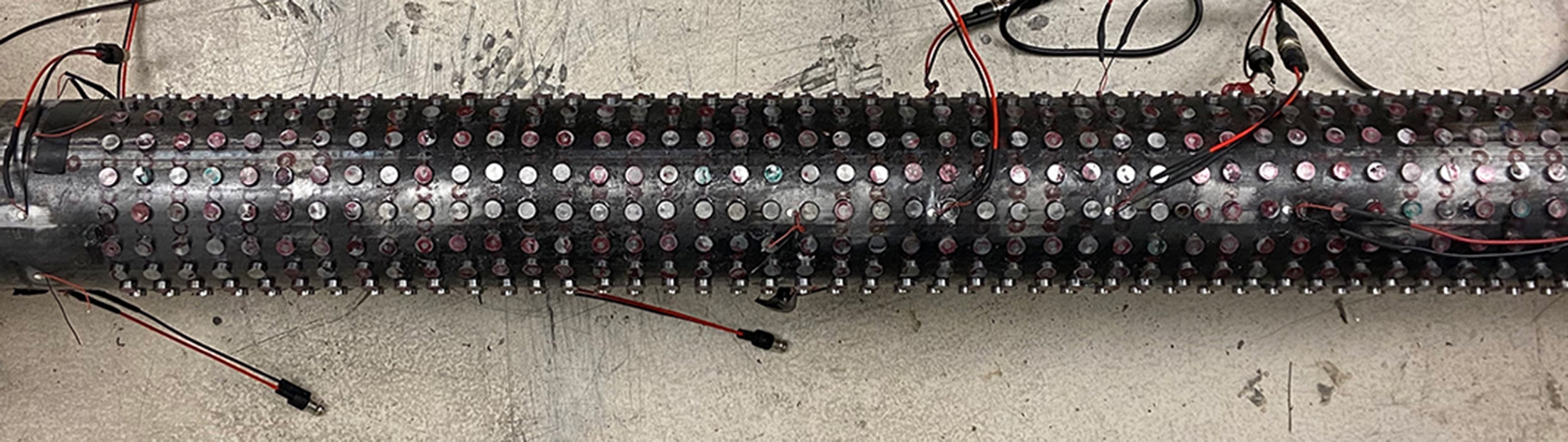

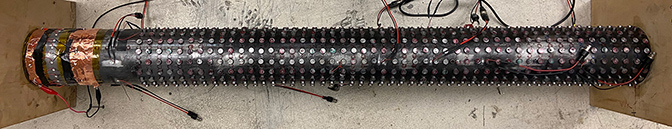

With our approach, the pipeline itself can be used to design a state-of-the-art passive waveguide. We tailor phononic crystals to guide and localize the elastic wave energy at a desired spot on the pipeline. We create a phononic crystal lens, much like an optical lens, and integrate it with existing pipe structures.

The goal is to amplify the vibrational energy at the sensor locations on the pipeline. The sensor produces an electrical signal to match, which is then converted to give us the speed of the waves.

We verified our lens design through numerical simulations and laboratory experiments on a prototype steel pipe. We observed twice the amplification of wave energy at the focal location as compared to the conventional pipe. The single lens design can focus multiple pipe wave modes commonly used for ultrasonic inspection of pipelines, each with their own specific advantages.

Our design also focuses wave energy over a broad frequency range of 20 kHz to 50 kHz, the ultrasonic frequencies. That means multi-mode broadband wave focusing can be achieved with our conformal lens—enhancing sensing and detection capabilities in long-range pipelines.

We observed twice the amplification of wave energy at the focal location as compared to the conventional pipe. The single lens design can focus multiple pipe wave modes commonly used for ultrasonic inspection of pipelines, each with their own specific advantages. “

Serife Tol, Assistant Professor of Mechanical Engineering

The lens would be a structural component to the current design of the pipelines and can be implemented on various length scales with proper scaling of the design features. Also, the design can be implemented in underground buried pipelines with the lens embedded in the pipe wall or remain as an external layer for open pipelines. We are currently investigating the 3D printed conformal lenses for existing pipes and developing next-generation lens embedded pipeline structures.

Pipeline failures are a serious concern which impact all who are serviced by them as well as municipalities tasked with maintaining them. Ruptured lines carrying oil, sewage and petrochemicals pose serious threats to humans as well as the environment.

An effective way to avoid these failures is to conduct regular inspection/maintenance via monitoring the pipelines’ structural health. Prevention of line failures are a cost savings in themselves. But with our technology, continuous structural health monitoring would become much more effective via cost reductions for line replacement strategies and the ability to help extend the life of pipelines.

The proposed conformal lens concept can be extended to other structures, including wind turbine blades, girders, and foundations, as well as other civil, mechanical and aerospace applications.

The research referenced here was supported by the National Science Foundation.

Read the paper, “Conformal gradient-index phononic crystal lens for ultrasonic wave focusing in pipe-like structures.”