Organic solar cells reach record efficiency, benchmark for commercialization

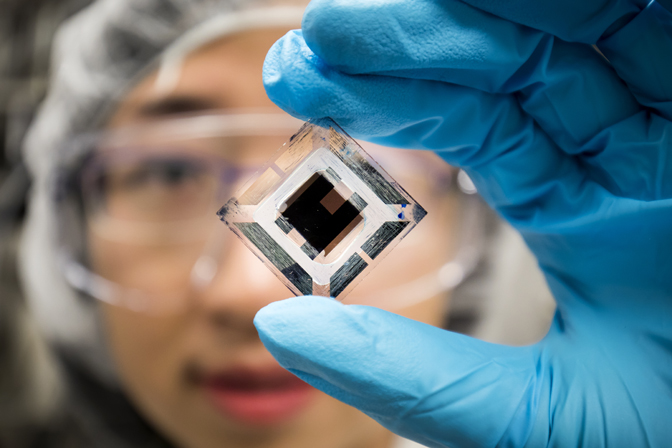

The multi-layered organic solar cells will be able to curve in clothing or be transparently built into windows.

The multi-layered organic solar cells will be able to curve in clothing or be transparently built into windows.

In an advance that makes a more flexible, inexpensive type of solar cell commercially viable, University of Michigan researchers have demonstrated organic solar cells that can achieve 15 percent efficiency.

This level of efficiency is in the range of many solar panels, or photovoltaics, currently on the market.

“Organic photovoltaics can potentially cut way down on the total solar energy system cost, making solar a truly ubiquitous clean energy source,” said Stephen Forrest, the Peter A. Franken Distinguished University Professor of Engineering and Paul G. Goebel Professor of Engineering, who led the work.

At 15 percent efficiency and given a 20-year lifetime, researchers estimate organic solar cells could produce electricity at a cost of less than 7 cents per kilowatt-hour. In comparison, the average cost of electricity in the U.S. was 10.5 cents per kilowatt-hour in 2017, according to the U.S. Energy Information Administration.

Organic solar cells incorporate carbon into their construction to offer several advantages over conventional “inorganic” cells. Silicon-based inorganic solar panels are costly to make—composed of thick, rigid sheets that require fixed installation points.

But carbon-based organic solar cells could be inexpensively manufactured in rolls that are thin enough to bend and curve around structures or within clothing, and made any color, even transparent, to blend in to their environment.

Organic photovoltaics can potentially cut way down on the total solar energy system cost, making solar a truly ubiquitous clean energy source.

Stephen Forrest, Peter A. Franken Distinguished University Professor of Engineering and Paul G. Goebel Professor of Engineering

Despite these advantages, organic solar cells have lacked the efficiency required to compete with conventional energy sources.

“For the last couple of years, efficiency for organic photovoltaics was stuck around 11 to 12 percent,” said Xiaozhou Che, a doctoral candidate in the Applied Physics Program and first author of a new study published in Nature Energy.

To break them out of this rut, the researchers combined multiple advancements in design and process.

First, they designed a system that combines specialized layers to absorb both visible and infrared light. Essentially they stacked two organic solar cells—one capable of absorbing light from the visible spectrum starting at 350 nanometers in wavelength, and another capable of absorbing near-infrared light up to 950 nanometers in wavelength.

“By themselves, the cells achieve 10- to 11-percent efficiency,” Che said. “When we stack them together, we increase light absorption and efficiency improves to 15 percent with an antireflection coating.”

Stacking the cells required a breakthrough in process. The team developed interconnecting layers that prevent damage to the first cell, and still allow light and electrical charges to pass through.

“That’s considered a difficult process because there’s a chance the liquid used in processing the top cell will dissolve the layers already deposited underneath,” Che said.

Organic photovoltaic efficiency

Finally, the team demonstrated that their new design, materials and process have a high fabrication yield of over 95 percent. This means the researchers successfully created almost all devices without short circuits, and is important for scaling up fabrication to an industrial level.

Despite setting record efficiency, the team believes they can push their progress even further.

“We can improve the light absorption to increase electric current, and minimize the energy loss to increase voltage,” Che said. “Based on calculations, an 18-percent efficiency is expected in the near future for this type of multijunction device.”

The study, “High fabrication yield organic tandem photovoltaics combining vacuum- and solution-processed subcells with 15% efficiency,” is published in Nature Energy on April 23, 2018.

In addition to Forrest and Che, study co-authors include Yongxi Li, a postdoctoral fellow in the Department of Electrical Engineering and Computer Science, and Yue Qu, a doctoral student in electrical engineering.

The work was supported by the SunShot Program of the Department of Energy and the Department of the Navy, Office of Naval Research.

Catharine June

ECE Communications and Marketing Manager