Advanced manufacturing lab opens in Detroit

Center to drive lightweight manufacturing technology

Center to drive lightweight manufacturing technology

A $50 million lightweighting research and development lab that the University of Michigan helped to jumpstart opened its doors today in Detroit’s Corktown district.

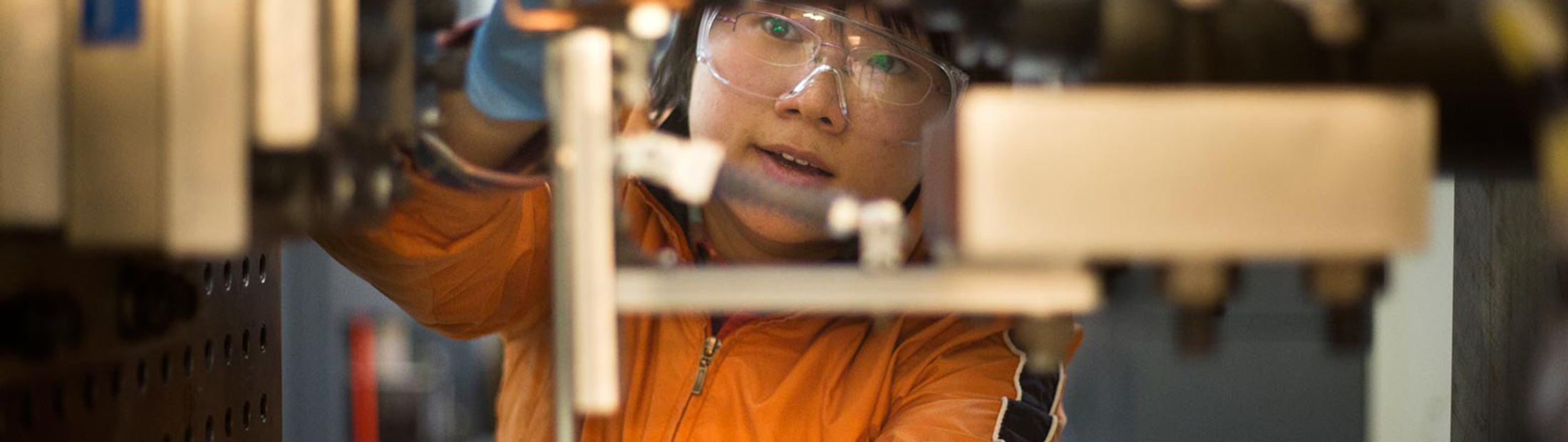

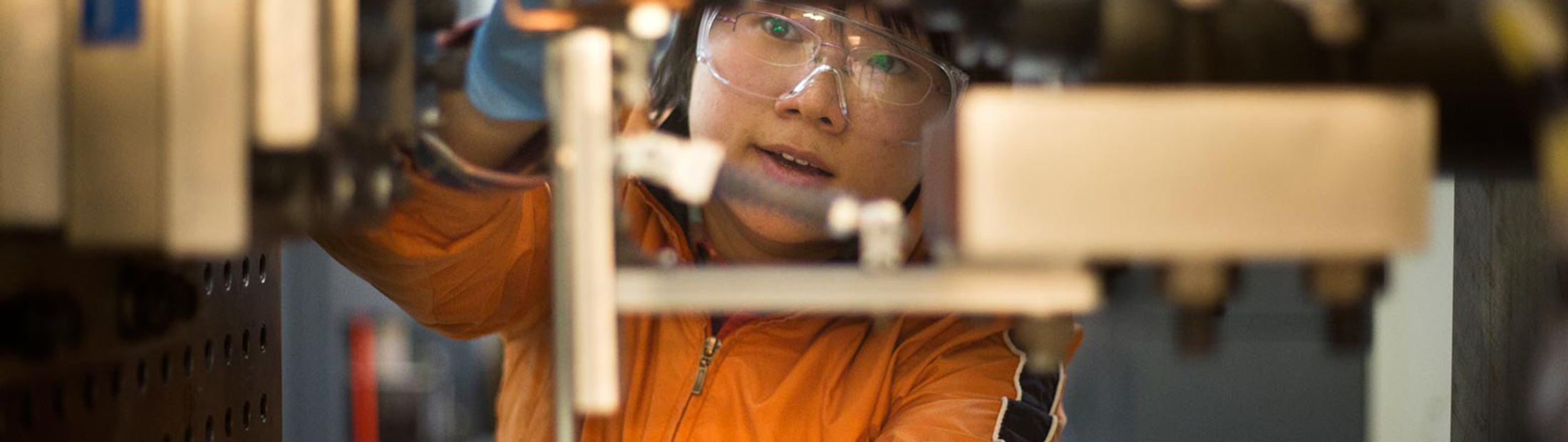

LIFT, which stands for Lightweight Innovations For Tomorrow, and IACMI, The Composites Institute unveiled the 100,000-sq.-ft. facility. It’s a cornerstone of LIFT’s effort to establish a regional manufacturing ecosystem that moves advanced lightweight metals out of the research lab and into tomorrow’s cars, trucks, airplanes and ships for both the commercial and military sectors.

“The metalworking industry in our country already employs almost half a million people,” said Alan Taub, LIFT’s chief technical officer and a professor of materials science and engineering and mechanical engineering at U-M. “Through LIFT technology advances and education and workforce programs, we are enabling further growth.”

LIFT, which was formerly the American Lightweight Materials Manufacturing Innovation Institute (ALMMII), launched in 2014 as a partnership among U-M, Ohio State University and Ohio-based manufacturing technology nonprofit EWI. The institute is a node in the National Network of Manufacturing Innovation, an Obama administration White House initiative to help U.S. manufacturers become more competitive. It is now called Manufacturing USA. U-M faculty played pivotal roles in helping to conceive and shape this network.

“The purpose of these manufacturing innovation institutes is to mature the technology and the manufacturing-readiness through precompetitive R&D and establish industrial commons necessary to anchor manufacturing in the U.S.”said Sridhar Kota, the Herrick Professor of Engineering at U-M and a professor of mechanical engineering. “LIFT’s six pillars of lightweight metals processing technology have significant applications to automotive and aerospace industries.”

Kota held an appointment as assistant director for advanced manufacturing at the White House from 2009-12. He proposed the idea of so-called Edison Institutes to bridge the “innovation gap” between basic research and manufacturing-readiness. Kota helped create Obama’s Advanced Manufacturing Partnership in 2011 to move the network forward. Other university leaders served on a working group of the Advanced Manufacturing Partnership.

These new institutes will help put the “&” back in R&D

Sridhar Kota

“These new institutes will help put ‘&’ back in R&D in order to get a better return on investment of taxpayers’ dollars,” Kota said earlier.

The new lab is a joint effort between LIFT and IACMI, The Composites Institute, which is another Manufacturing USA institute. It will allow institute members, partners and others in the industry to conduct research and development projects, in both lightweight metals and advanced composites. It will also provide education space for students and adult learners focused on the composites and lightweight materials industries.

With more than 74 member organizations including companies, universities, research institutions, and education and workforce leaders as partners, LIFT is expected to contribute to economic development and positive job impact in Detroit and stretching to the five-state region of Michigan, Ohio, Indiana, Tennessee and Kentucky over the next five years. Most of these jobs will be in the metal stamping, metalworking, machining and casting industries that are dominant in the Midwest region.

Beyond its R&D efforts, the institute aims to help educate the next generation of manufacturing’s technical workforce. LIFT will engage workforce partners from across the region to strengthen education and training pathways to high quality jobs in all transportation manufacturing sectors, including the automobile, aircraft, heavy truck, ship, rail and defense industries.

LIFT receives federal funding as well as funding from the consortium partners themselves, including the Michigan Economic Development Corp. and the state of Ohio.