The Michigan Probe: Changing the Course of Brain Research

Some believed early Michigan brain researchers were engaging in “science fiction” – until development of an advanced tool for forging breakthroughs proved them wrong.

Some believed early Michigan brain researchers were engaging in “science fiction” – until development of an advanced tool for forging breakthroughs proved them wrong.

National research budgets now allocate millions to developing better tools for neuroscience through programs such as the U.S. BRAIN Initiative and Europe’s Human Brain Project. But Kensall Wise, the William Gould Dow Distinguished University Professor Emeritus, remembers a time when technology for brain research was on the fringe.

“When we started, we couldn’t get money from anybody,” said Wise, also a member of the National Academy of Engineering and a professor emeritus of electrical engineering and computer science (EECS) and biomedical engineering. “One reviewer, as I recall, referred to it as science fiction. But back then, he was probably right.”

Since his graduate student days in the late 1960s, Wise has seen technology for neuroscience grow from a very small, underfunded community to a large and diverse field. Now, he and other electrical engineers, computer engineers, and computational neuroscientists are rapidly expanding our neurological knowledge base. And the turning point, changing neural probes from laboratory curiosities into useful tools, occurred at the University of Michigan.

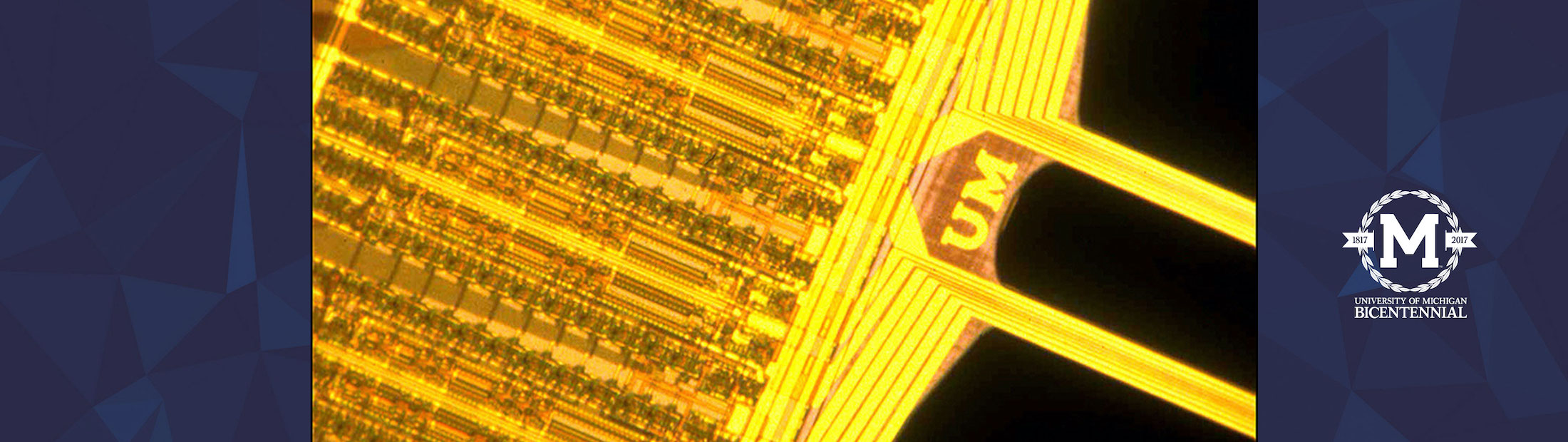

Beginning in 1981, Wise and his collaborators at Michigan developed a series of neural probes, or devices capable of measuring and influencing activity in the brain at the cellular level. The initial innovation was their use of manufacturing techniques borrowed in part from the rapidly growing microelectronics industry. Made at Michigan and given to neuroscientists around the country to facilitate brain research, they became known in the field as the Michigan probes.

“Prior to Ken Wise’s revolutionary silicon probes, every neuroscientist used either wire or glass electrodes,” says György Buzsáki, the Biggs Professor of Neuroscience at New York University and long-time user of the Michigan probes. “However, those electrodes have only one useful site: the tip. The rest is just inconvenient bulk that damages the brain tissue. Silicon probes allowed us not only to record from multiple brain sites but also from a very small volume of tissue with high spatial resolution.”

For the first time, researchers could simultaneously record from neighboring neurons while also distinguishing their individual signals. They could begin to piece together how neurons form electrical circuits in the brain.

According to Wise, the vision for these neural probes was that they would enable experiments leading to a better understanding of the brain – and that they might one day deliver the precise stimulation needed to treat disorders such as deafness, blindness, epilepsy, Parkinson’s disease and perhaps paralysis.

Decades of development and experimentation have produced a greater appreciation for the brain’s complexity, but many of its aspects remain mysterious. Medical applications are only beginning to be realized, with treatments such as cochlear implants for people with hearing loss and deep brain stimulation suppressing Parkinson’s tremors, and early stage visual prostheses providing limited sight to the blind. But Wise believes that neuroscience finally has the momentum to start producing more and better medical solutions.

A practical probe

If the course of history had run a little differently, the Michigan probe might have been the Stanford probe. It was at Stanford University, as a graduate student, that Wise produced his first neural probes, but he went through a lot of silicon trying to make them.

The problem was producing a shank ten microns across – or ten thousandths of a millimeter – from a silicon wafer 200 microns thick. Wise used a strong base to remove 190 microns of silicon, but it was easy to burn clear through. It was difficult to shield parts of the silicon from the etchant, and if the temperature was too high or low, it would affect the etching rate.

In 1970, Wise and his colleagues published a paper describing the new silicon probe, showing that it could record from neurons at more than one site. But after completing his PhD, Wise turned to research topics with more reliable funding.

Wise said of the first batch, “They were gorgeous. Our family was ready to leave for Disney World on a vacation, and I took some of the pictures with me, I was so excited about them.”

After joining the Michigan faculty in 1974, the neural probe work remained shelved until 1981, when Wise received a phone call from an agent of the National Institutes of Health. “They were thinking of generating a request for proposals in the area and basically asked me whether I would bid on it if they did,” said Wise.

Together with colleagues in electrical and computer engineering, including members of the Bioelectrical Sciences Laboratory, Wise proposed a project to expand and test the capabilities of silicon-based neural probes. Wise’s team made the probes while the bioelectrical contingent ran local tests at the Kresge Hearing Institute in the medical school. And through an epic series of 3-year renewals, Michigan maintained that grant for roughly 25 years.

The biggest hurdle, Wise knew, would be making the probes reliably. “Unless you can build enough of them so that you can give them to other researchers to use, you’re really not going to influence the field very much,” said Wise.

By this time, other researchers had discovered that if silicon is heavily infused with boron, the etching process almost comes to a halt. It was relatively straightforward to pattern the silicon by diffusing boron into it, in the shape of the probe. Now, stopping the etching process at the right time no longer required superhuman control. The team had broken through the bottleneck preventing them from reliably manufacturing the probes.

Wise said of the first batch, “They were gorgeous. Our family was ready to leave for Disney World on a vacation, and I took some of the pictures with me, I was so excited about them.”

Customized service

Once the team could make the probes in quantity, they needed to optimize the rest of the design – including circuitry that would allow them to record from particular sites on the probe, provide signal amplification and processing capabilities, and help minimize the physical footprint of the device. Researchers wanted to record the brain activity of rodents that were free to move around so that long-term studies would be feasible and brain activity could be linked to behavior. For this, the team had to make the probe as unobtrusive as possible to both the animal and its immune system.

In the 1980s, wireless technology wasn’t yet available on tiny scales, so they had to minimize the size and number of wires. The signals from multiple sites had to be preprocessed on the probe so they could run through one wire.

Buzsáki’s team started working with Wise’s group in the early 1990s. After testing some basic probes, they designed a six-shank probe with 24 recording sites. With it, they discovered a new pattern of brain activity in the hippocampus – the part of the brain responsible for memory – by looking at a collection of 50 neurons inside the hippocampus of a rat.

“Most secrets of brain coding occur super-locally,” said Buzsáki, and the silicon probes were ideal for studying these local interactions. By putting probes in different brain structures, his team could observe how a pattern in one part of the brain affected neural activity in another region.

“Almost every structure in the brain requires a custom-made probe for a particular goal. After each successful experiment, we wished for more,” said Buzsáki. His group’s collaboration with U-M continues to this day, although the program funding the original Michigan probes ended in 2006.

In its various iterations, Michigan probes also have included microfluidic circuits to manipulate brain activity by delivering drugs at a cellular level. The Center for Neural Communication Technology, initially led by David Anderson, now a professor emeritus of biomedical engineering, distributed probes to researchers around the country.

Wise estimates that during the quarter-century of funding by the National Institutes of Health, they produced nearly 10,000 probes for researchers in neuroscience laboratories. Feedback from these users helped to guide probe designs – more than 100 in all – to achieve better results.

The spinoff

Demand for Michigan probes was great enough that some members of the team formed the spinoff company NeuroNexus in 2004. Daryl Kipke, formerly a professor of biomedical engineering and Anderson’s successor at the helm of the Center for Neural Communication Technology, is now the president. He says the company has expanded access to the probes across 40 countries, to other academic labs, and to industry – and he estimates that only 10 to 20 percent of its current customers are former Michigan probe users.

The neurotechnology programs at Michigan are largely responsible for making probes with many recording sites affordable. Before the Michigan probes, a neural probe with 128 recording sites had to send that information through 128 amplifiers and 128 data wires. Such a system cost more than $250,000, according to Buzsáki. Now, through NeuroNexus, one of Buzsáki’s probe designs can send data from 256 sites over just a few wires, at a cost of less than $10,000.

With the demand for custom probes, NeuroNexus has dramatically accelerated the turnaround time for new designs – from a few months to a few weeks. Jamille Hetke, who also started out working on Michigan probes and is now an Engineer Fellow at NeuroNexus, notes that the company is also working on probes for medical applications.

The continuing legacy

The importance of the Michigan probes extends well beyond neuroscience. The effort was instrumental in supporting the growth of a new field: MEMS, or microelectromechanical systems.

Demand for Michigan probes was great enough that some members of the team formed the spinoff company NeuroNexus in 2004.

“Many of the technologies, the knowledge, and ideas that we worked on in those early days found use in many, many other areas and projects that had nothing to do with implants,” said Khalil Najafi, one of Wise’s early PhD students and now chair of the electrical and computer engineering division of EECS. For his thesis, Najafi developed a probe with on-board processing and amplification electronics so that data from 10 recording sites could share a single wire.

“The Michigan probe program not only had a huge impact on the entire field of neural implants, it also had a huge impact on the entire field of MEMS, here at Michigan, and elsewhere,” Najafi added.

MEMS is typically concerned with systems, including sensors and microprocessors, that are smaller than a few millimeters across. Its applications include inkjet printers, a variety of sensors for medical devices, accelerometers and gyroscopes for vehicles and consumer electronics, microphones for mobile phones and laptops, and many other devices that turn non-electronic signals into electronic data.

The neural implant program spurred the development of the Solid-State Fabrication Facility in 1996, which became the Lurie Nanofabrication Facility in 2008, and paved the way for the Center for Wireless Integrated Microsystems (WIMS), awarded to U-M by the National Science Foundation in 2000.

And while the NIH project that produced the original “Michigan probes” wrapped up a decade ago, researchers in EECS continue to develop ever more complex neural probes built on silicon shanks. The latest iteration incorporates minuscule LEDs developed by Euisik Yoon, a professor of EECS. In genetically modified mice, it is possible to switch neurons on and off with light, revealing the roles that these neurons play in brain activity. This probe is the first that can restrict the light’s effects to just a few neurons at a time. And Buzsáki ran the first tests.

To learn more about the LED-equipped neural probes, see this 2015 Michigan Engineering story about brain mapping.