This bot’s got game

Building a ball-chucking, bar-climbing, battle-ready robot in 72 hours.

Written by:

Photos by Brenda Ahearn & Marcin Szczepanski, Michigan Engineering

If you give an engineer a ball, they’ll want to build a robot that can play with it. That was essentially the challenge of the 2022, Robot in Three Days (Ri3D) competition. These photos document the 72 hours in January that student teams had to design, build, wire and program a robot that could maneuver around a play surface, scoop up balls and score points by chucking them into two goals of different heights. Robots that could climb a series of parallel bars could earn even more points. The two groups competed against three other teams from Michigan State University, Grand Valley State University and Kettering University in a competition held February 12, 2022 at Grand Valley State University, near Grand Rapids, Mich.

But it wasn’t just about total robo-domination. The larger goal for all five teams was to blaze a trail for dozens of FIRST Robotics high school teams from around the country who were tasked with building robots to meet the same challenge. They, however, had six weeks to complete the task, and they had access to videos, tutorials and more from the college teams.

What goes into building a robot in three days? It starts with the biggest tennis balls you’ve ever seen, and the rest is up to the builders.

SPEC IT

The FAMNM team waits to receive the code that will unlock the specifications and requirements for this year’s competition. Every Ri3D team gets the code at the same exact moment, kicking off 72 highly caffeinated hours of design, debate and wrenching. From left to right: Dominik Kerschbaum, Nuotianghong Xu, Krishna Dihora and Pirro Marko.

DEBATE IT

The FAMNM team’s Taubitz (left) and Williams talk strategy. After a quick initial brainstorm, the team broke into subgroups to tackle individual problems like coding, control interface, wiring and mechanics.

WIRE IT

Jack Ferguson (left) and Bluejay Cyanocitta of the Zone for Engineering Mentors (ZEM) team discuss how to wire the shooting mechanism of their robot. Because the competition has multiple targets with different point values, teams must be strategic about which targets to prioritize.

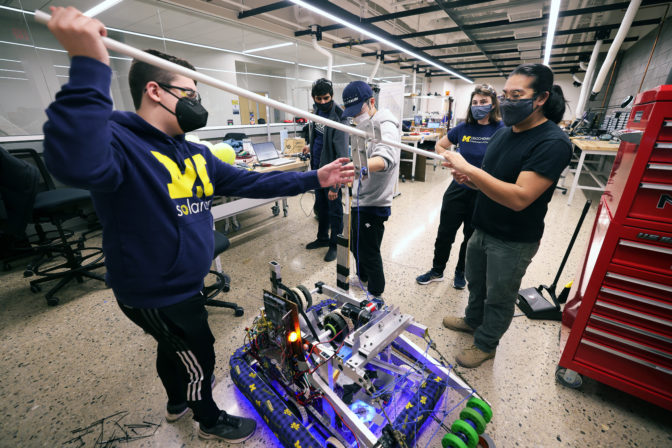

WRENCH IT

The FAMNM team builds the climbing mechanism that will (hopefully) enable their robot to earn additional points by hoisting itself up a series of bars using a hook, telescoping rod and winch mechanism. The complex mechanics of building a climbing robot were a big challenge for both teams. What goes into building a robot in three days?

Working on this took an insane amount of dedication and an even more insane amount of caffeine. We probably spent 20 hours a day working, but there is a point where you just have to stop for a minute and take care of yourself.”

Edward Ivanak, ZEM team

CHECK IT

Cyanocitta (left) and Ferguson of the ZEM team measure the height of their robot’s climbing mechanism. The competition has strict size limits, so a robot that’s too tall could get the team disqualified.

DROP IT

Marko watches a ball hurtle out of the FAMNM team’s robot toward the second floor of the Ford Motor Company Robotics Building as a teammate waits to catch it.

Not their first robo-deo

Many of the ZEM and FAMNM builders have been building robots since high school or even middle school, so they’ve been on both sides of the equation and they take pride in bringing the next generation on board.

“I think robots are a really great entrance into the world of STEM, and it’s more than just the engineering aspect,” Kerschbaum said. “Being able to communicate your ideas to other people, especially when you’re under a limited timeframe, is one of the biggest lessons, and it’s just really cool working together with other people to solve a challenge.”

The ZEM team works directly with Southeast Michigan high school students at U-M’s Michigan Engineering Zone, or MEZ. Located in Midtown Detroit, the MEZ provides students with STEM resources, instruction and counseling.

“I was a high school student who didn’t know what I wanted to do, but I had these kinds of resources, and now I want to be an electrical engineer who works in robotics,” said Ivanak. “And I know that I can give that back to another student who will continue that cycle.”

The teams

FAMNM

Jonathan Brandell, Krishna Dihora, Jade Ebels, Corbin Fleming-Dittenber, Camber Hortop, Dominik Kerschbaum, Rebecca Jean, Yiliang Liang, Pirro Marko, Brighton Pauli, Ben Poole, Grace Shenefelt, Tim Taubitz, Nuotianghong Xu

ZEM

Bluejay Cyanocitta, Jack Ferguson, Servando Garza, Max Gusukuma, Jorge Huerta, Ted Ivanac, Govind Suresh, Elijah Underhill-Miller