U-M Battery Lab to join Michigan Materials Research Institute

The move will help drive production-level research into next-gen solid-state battery technologies.

The move will help drive production-level research into next-gen solid-state battery technologies.

In an effort to drive the commercialization of more affordable, higher-capacity batteries for electric vehicles and grid storage, the University of Michigan’s Battery Fabrication and Characterization Facility will join the Michigan Materials Research Institute (MMRI).

The North Campus facility, better known simply as the Battery Lab, enables academic and industry researchers to work together to build and test batteries. It was formerly housed in the U-M Office of the Vice President for Research.

Alan Taub, the founding director of the MMRI and professor of materials science and engineering and mechanical engineering, says transitioning the lab to the MMRI, which is housed in the College of Engineering’s Materials Science and Engineering department, will help position it for the major changes coming to the industry.

“The battery lab is an amazing facility that’s already at the forefront of the industry’s massive shift toward batteries that use new classes of materials,” Taub said. “And because the MMRI is involved with materials science research across the university, I anticipate that we’ll be able to catalyze new collaborations and research.”

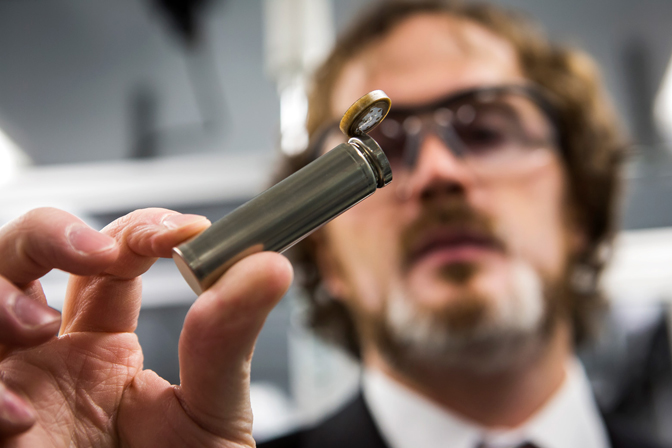

The move will help the lab scale up research on newer solid-state battery technologies like lithium metal, said lab manager Greg Less. He explains that ramping up research to the production level will require new capabilities and investments, since solid-state batteries use more reactive materials that require tighter control over production variables like humidity.

To that end, the MMRI is facilitating the installation of a $1.2 million dehumidification system in the Battery Fabrication and Characterization Facility, as well as other production line improvements that will enable more precise mixing of materials and streamline production of finished solid-state batteries.

“I’m looking forward to adding new capabilities to our production line, like the ability to work with high-nickel content materials and new cathode research,” Less said. “We’ll be gaining new resources in IT infrastructure and communications infrastructure as well.”

Founded in July 2019, the MMRI is a central point of contact for federal agencies and industry, providing easy access to the many disciplines that underpin materials science research and driving collaboration within the university. Its team integrates efforts from a wide range of disciplines including mechanical engineering, chemistry, computer science, biomedical engineering, dentistry, physics, nuclear engineering, chemical engineering and aerospace engineering in addition to materials science.

The Battery Fabrication and Characterization Facility provides critical infrastructure for the characterization, scale-up and testing of existing and next-generation energy storage materials and devices. The facility creates new capabilities for in–situ characterization of battery materials and devices under working conditions. This infrastructure investment is key to achieving the breakthroughs needed to make both electric vehicles and grid storage viable at the scales needed for the future.

The facility is supported by Ford Motor Company, the Michigan Economic Development Corporation, the College of Engineering and U-M. It supports the Joint Center for Energy Storage Research (JCESR), vehicle electrification R&D programs, and ARPA-E-funded research on solid state batteries.