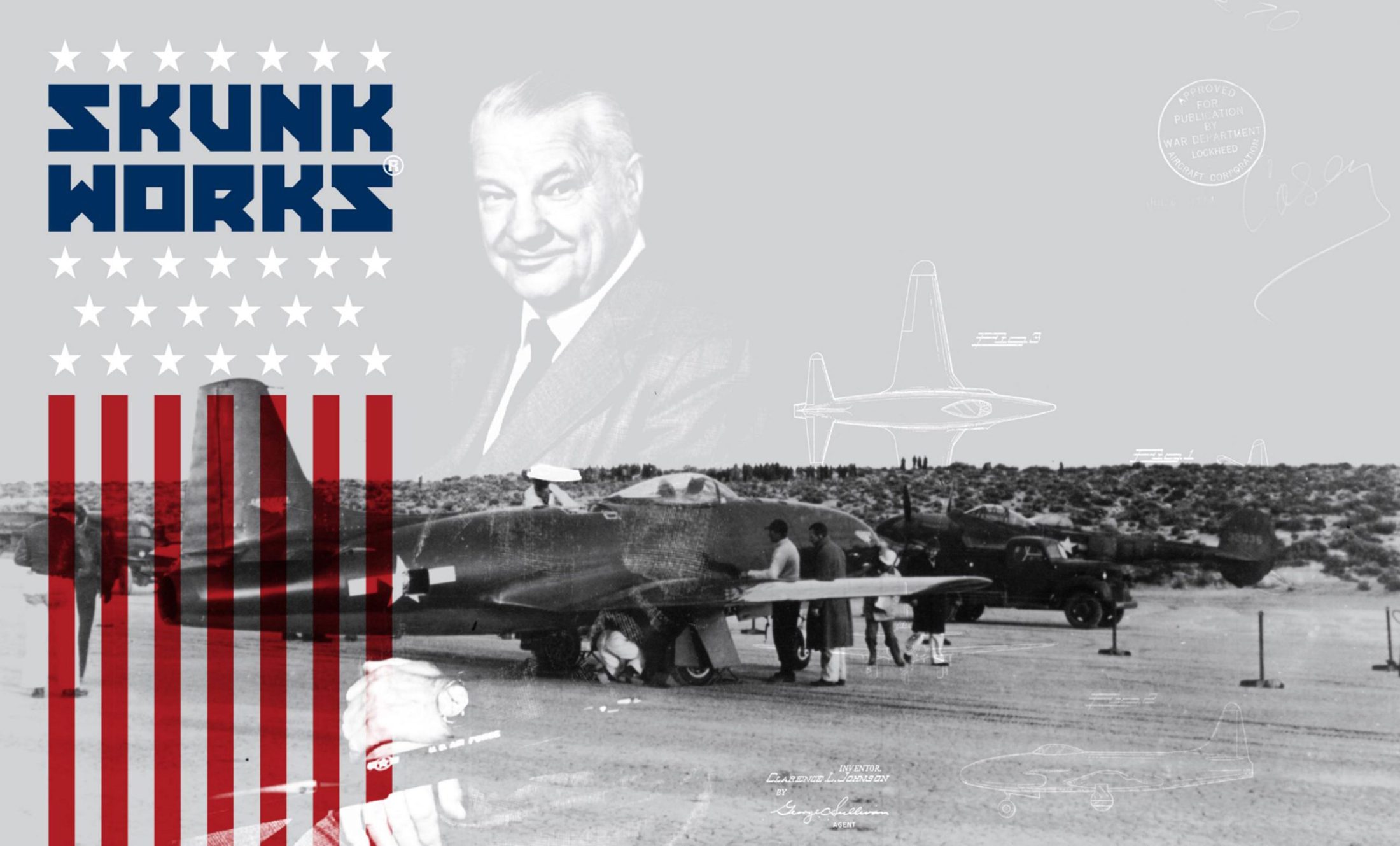

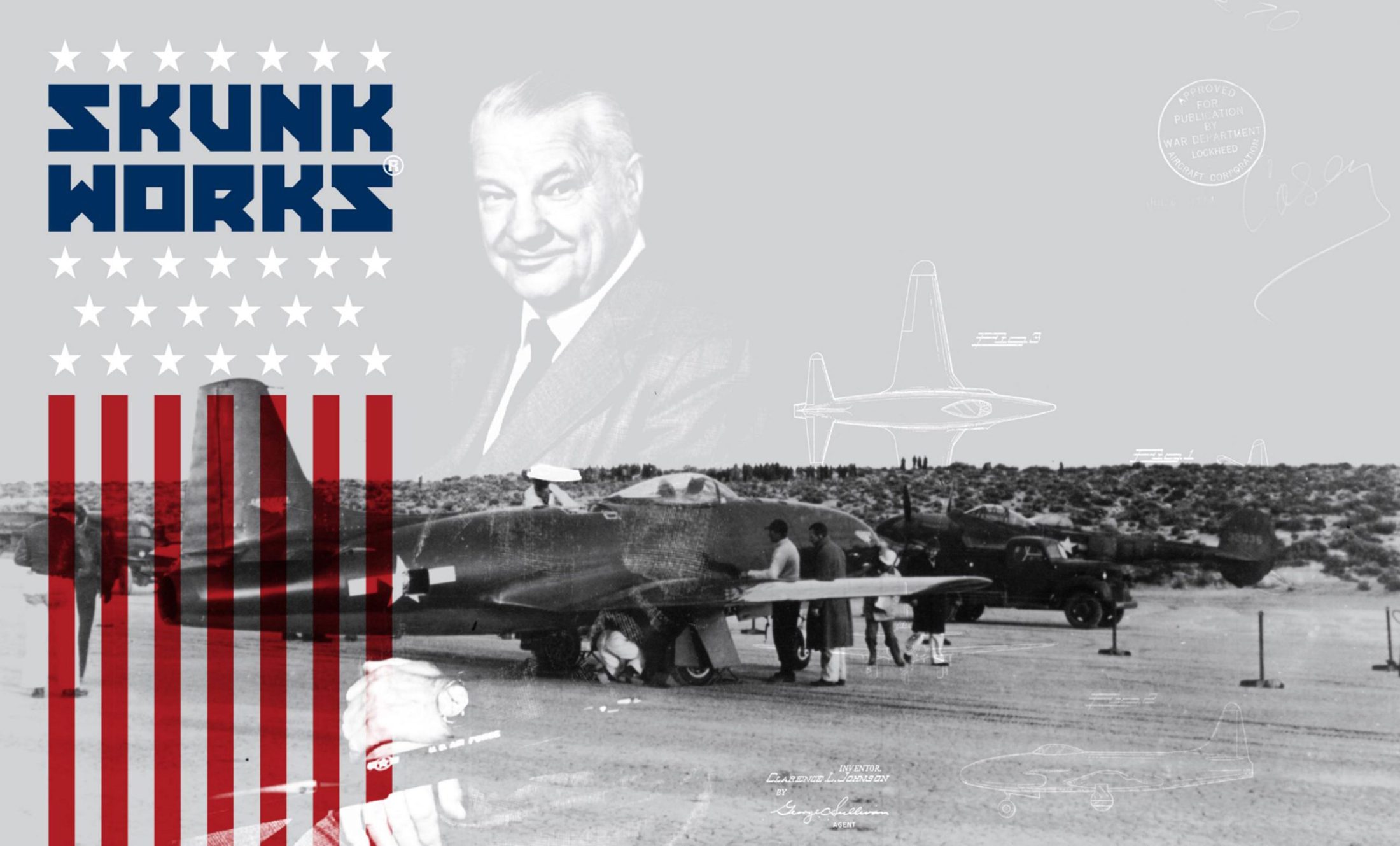

Skunk Works

Though the urgency for the Shooting Star might have been exaggerated, the Nazi threat, coupled with Johnson’s peculiar characteristics, was perhaps the only way such a unique operation might ever have been formed in the first place.

Though the urgency for the Shooting Star might have been exaggerated, the Nazi threat, coupled with Johnson’s peculiar characteristics, was perhaps the only way such a unique operation might ever have been formed in the first place.

By Randy Milgrom

IT’S 1943 — IN THE THICK OF WORLD WAR II — AND A NEW GERMAN JET FIGHTER IS MENACING THE SKIES OVER EUROPE. AMID MOUNTING FEARS, ARMY BRASS TURNS TO MICHIGAN ENGINEERING ALUMNUS CLARENCE “KELLY” JOHNSON TO THWART THE NAZI THREAT.

The Nazi regime had been trying to develop a jet aircraft since well before the onset of World War II, and in mid-1943 it introduced the world’s first operational jet-powered fighter — the Messerschmitt Me-262 Schwalbe (“Swallow”). German officers viewed its most effective use as a fighter against Allied bombers, but Adolf Hitler — infatuated with the Me-262’s superior speed — liked its potential as a high-speed, light-payload Schnellbomber (“fast bomber”). And as this brief Nazi debate took place, the Allies still were flying nothing but propeller planes.

On June 17, 1943, Clarence “Kelly” Johnson, Lockheed’s 33-year-old chief engineer, was at the U.S. Air Corp’s Eglin Field in Florida, observing the performance of the latest version of his P-38 Lightning war plane.

This was the day Johnson (BSE AeroE ’32, MSE ’33) first learned — as Wright Field’s Colonel M.S. Roth sidled over to confide in a whisper — that the U.S. military was testing a new U.S. Bell jet.

“You wanted to build a jet for us once,” Roth reminded Johnson. But Johnson didn’t need any reminders.

Johnson and Lockheed had developed the P-38 beginning in 1937. And though it still was the nation’s fastest propeller-driven fighter, Johnson had only been able to increase its speed by a mere 17 miles per hour — even while nearly doubling its power. In 1939, with the Brits and the Germans working feverishly on jet turbines, Johnson proposed his own audacious new jet design that he claimed would approach the speed of sound. But the Air Corps — more eager for more planes to fly more immediately into battle — turned him down flat.

England’s Frank Whittle had since made significant progress on a jet engine — with Germany’s Ernst Heinkel remaining consistently ahead of his pace. But the U.S. military had only timidly experimented with a Bell P-59 jet, which proved ineffectual.

Now, a very worried U.S. Army Air Force was obsessed with the Messerschmitt Me-262 — Germany’s latest, superior jet fighter — and the very real prospect that the enemy German Luftwaffe would soon be dominating the skies over Europe. The Me-262 was much faster and better armed than any plane in the Allied arsenal. It was striking terror in every military officer with awareness not just of its current capabilities, but of its fearsome potential wrath — and consuming their every waking thought. What the Hell was that?

Worse, a reluctant Roth confessed to Johnson, this new U.S. Bell jet’s performance had been deeply disappointing. Like the old, tentative Bell jet introduced several years earlier, this new one was flying barely faster than Johnson’s propeller-driven Lightning.

And now Roth — finally! — was asking Johnson if he would be willing to try again.

Roth told Johnson the top-secret jet plane would need to fly more than 100 mph faster than the Lightning. It would need to fly more than 500 mph to combat the Nazi fighter.

“Just give me the specs,” Johnson growled.

Johnson had scribbled nonstop on the backs of envelopes and in the margins of magazines on the flight back to Burbank from Florida. As soon as he stepped off the plane at Lockheed’s Air Terminal, Johnson bolted up the stairs to Lockheed President Robert Gross’ office, where Gross and Johnson’s boss, Hall Hibbard, were waiting.

It was a hot day in June, and Johnson was about to be grilled by his Burbank bosses about his Eglin Field encounter with Col. Roth the day before. But the robust Johnson’s demeanor remained forceful, his expression self-confident, his black hair slicked and neatly combed.

Once inside the inner sanctum, Johnson launched right in.

“The Army Air Force wants us to submit a proposal for building a plane around a jet engine. I’ve worked out some figures. They want it fast, and I think I can promise 180-day delivery. What do you think?”

“180 days!” Gross stammered.

That schedule seemed nothing more than a fantasy. No company ever had designed and built any kind of prototype in anywhere near that kind of time — let alone a prototype for a jet fighter. But this was different. This was a top-secret assignment to develop a critical weapon to beat back the Nazi threat. This would be the most important challenge in American aviation.

A brief round of hand-wringing and head-shaking followed. But if either Gross or Hibbard thought of saying “no,” neither said the word aloud — and Johnson went straightaway to a drawing board to resume his calculations.

Within the week, Johnson had packed up numerous sketches and dozens of pages of detailed specifications and hand-delivered them to Gen. Frank Carrol, commanding officer of Wright Field.

“We’ll give you the contract,” Carrol told Johnson.

Johnson had promised Roth a prototype in 180 days — and the high command was just desperate enough to believe him. “You better get moving,” Carrol told Johnson. “This is Day Number One.”

And before the day was out, Johnson was back on a plane to Burbank, letter of intent in hand.

“It’s your baby,” Gross told Johnson, now back at Lockheed. But Gross remained skeptical about the ridiculous time demands.

“I don’t think anything will come of it, but you’ve brought this on yourself,” Gross said. “We’ll give you all the help we can, but you’ve got to rake up your own engineering department and your own production people and figure out where to put this project. Now go set up shop.”

Lockheed already was building 28 military planes a day. There were no spare engineers, and no spare machinery or space. But Gross’ admonition sounded like a dream finally realized for Johnson, who had long pestered Gross and Hibbard for an experimental shop in which a small group of talented design engineers, mechanics, and manufacturers could work together without complication or delay.

The Army promised its full cooperation, and six days after Johnson left Wright Field, all the equipment it was obligated to provide — guns, radios, tires, wheels, air-speed indicators, and other instruments — had arrived at Lockheed’s Burbank plant, ready to be installed as the design and construction schedule rolled out. To ensure the availability of all other tools that couldn’t be spared from its ongoing production line, Lockheed bought out an entire local machine shop.

Johnson’s willful personality and reputation played no small part in the wide berth granted Johnson by the Lockheed and Air Corps brass. With so much at stake, responsibility and authority would need to be concentrated in just one man — and only one man was qualified. As much a salesman as a designer and engineer, Johnson was an energetic promoter who knew how to dominate meetings, even among military personnel well accustomed to having their way.

To the extent possible, this experimental shop would need to behave as a single person. And to fully exploit his autonomy, Johnson sought to set up far away from the office and shops, in an open area adjacent to the plant’s wind tunnel — which offered three distinct advantages. It was at the extreme end of the complex, where few others operated. Its proximity to the wind tunnel would prove useful and convenient for testing, as needed. And on the far side of this remote area sat a noxious plastics factory, whose stench would keep the curious at bay — and soon the group would be nicknamed “Skunk Works.”

Johnson had plant engineering clear the space beside the wind tunnel, and within 10 days they had slapped together a drafty and unheated temporary structure covering 11,000 square feet. Ordinary construction materials were scarce in wartime, so the crew cobbled its walls with huge old Wright engine crates left over from deliveries for the Hudson bomber, assorted scrap lumber and canvas. And for the roof, Johnson rented a giant circus tent.

Now Johnson put on his overalls and brazenly walked around the factory, “stealing” — as he put it — the company’s top people. People who would be willing to work under the motto Johnson had embossed on his notebook covers:

“Dammit..Do It.”

Clarence Leonard Johnson — nicknamed “Kelly” as a grade-schooler — was smart, hard working and intensely ambitious. As a scholarship student at Michigan Engineering (BSE AeroE ’32, MSE ’33), Professor Edward Stalker hired him as his wind tunnel assistant, and when Johnson disagreed with his professor’s assessment that Lockheed’s new twin-engine Electra was stable, he was immediately overruled. But the brash Johnson didn’t hesitate to reiterate his concerns to Lockheed, which had hired him soon after he graduated.

His Lockheed superiors suppressed their first thought — which was to fire him — and instead sent Johnson back to the Michigan wind tunnel with the big Electra model crammed into the back seat of his car. Subsequent tests and modifications — including the unconventional twin-tail design that would become his signature — not only vindicated Johnson, but returned him to Burbank a hero.

Johnson knew a formal contract between the parties would not be forthcoming for months — but the signed letter of intent dated June 22, 1943, nonetheless obligated the just-formed Skunk Works to deliver the prototype airframe before Christmas.

The design of the prototype — officially the XP-80 but affectionately called the Lulu Belle (and later the Shooting Star) — was uncomplicated enough, theoretically, to construct within this sped-up timeframe. But to keep every man firmly focused on the unrelenting passage of days, Johnson installed a big scoreboard countdown calendar — a large red sign attached to the back wall entitled, “Our Days Are Numbered.”

Every morning, the preceding day would be pulled off — and the new day recognized. Work seemed to have just begun, but there it was: “This is Day No. 14: 166 to go.”

The clock was ticking. But rather than hearing the sound it made, the crew’s 23 engineers and its ever-expanding staff of shop mechanics actually watched each day torn from its moorings. Johnson hated to have to do this. Coming to grips with another day coming and going was difficult for everyone. But time pressures were intense — and Johnson wanted his men to know it.

On Day No. 19, the crew finalized a wooden mock-up of the airplane — the project’s first substantial completion milestone — right on schedule. Johnson wanted to make the mockup unusually detailed to discourage changes, and when Air Force personnel arrived from Washington for the inspection, no changes were made.

Later it was discovered that the occasional walks mechanics needed to take along the wings’ surfaces were causing slight displacements that still were significant enough to throw the plane out of trim. The crew worked on various fixes, but Johnson ultimately implemented a modification that improved the craft’s stall characteristics — which also made the plane less sensitive to minor wing contour changes.

As the mission neared its halfway mark, the men struggled to develop an optimally aerodynamic fuselage that would also readily accommodate engine and armament installation and repair. Finally they devised a workable wing section redesign, and the moment draftsmen finalized updated blueprints, mechanics were building the sections. The redesigned wings were completed — and ready for mating to the fuselage — on Day No. 83.

Which — according to Johnson’s master schedule — was just in time.

In September 1943, the Luftwaffe introduced a jet-powered bomber — the Arado Ar 234, with an estimated maximum speed of 480 mph and a range of 1,240 miles. But this was still a prototype — the Nazis had not yet made the aircraft fully operational — and during a prototype test flight on October 2, 1943, it dived into the ground from nearly 4,000 feet and crashed at Rheine, near Münster. Both of the plane’s engines had failed, a wing had caught fire — and its pilot died instantly upon impact.

When Johnson had his meeting with Gen. Carrol at Wright Field, Carrol had not only approved a contract for the prototype but for a new Lockheed-designed jet engine as well.

“But you’ll have to use the new engine the British have promised us in the first airplane,” Carrol told him. “We’ll need it — and all the jet fighters you can build — as soon as possible to use against the Me-262. Your new engine couldn’t possibly be ready for service in time.”

The British engine in question was not the Whittle-designed turbine used in the failed Bell jet, but a new de Havilland design.

“What’s it look like?” Kelly had asked Carrol.

“Sorry, Kelly. It’s top secret. We can’t tell you.”

Johnson and Lockheed had accepted these terms, of course, but the most difficult aspect of the mission had always been working without an engine. The engineers knew only that they were building an urgent prototype, and only five knew it was for a jet plane. The Air Corps gave Johnson some drawings and specifications, but most knew absolutely nothing about the engine. And not one person — not even Johnson — had ever seen it.

The Army Transport Command had promised to fly the engine from London to Burbank, but still there was no sign of it.

And to make matters worse, the sickness rate among the men was climbing. Johnson believed in working smart — and working longer than was healthy or productive in a cold and drafty building was just plain stupid. From Day No. 1, Johnson had based his production schedule on a 10-hour day/six-day week, with work on Sunday strictly forbidden. Now, as the days on the scoreboard dwindled, a 25 to 30 percent absentee rate was reaching 50 percent or more.

“By coming back in here on Sunday, you are hurting the project,” Johnson said, doubling down on his insistence that the rule be obeyed. “You don’t get enough rest and you get sick. The next man I catch in here on Sunday goes back to the B-17s.”

The crew ran and re-ran safety tests, anticipating the engine’s arrival. The days passed, one after another, and the mornings and evenings grew chill. More anxious than ever to test the plane’s engine before its crucial aerial debut, Johnson and his top aides were starting to fret.

When the transport finally arrived — on November 3, 1943; Day No. 132 — it carried not just the engine but a British civilian expert technician. Exhausted from the long flight, the Englishman asked if he could go to his hotel in Hollywood for a brief rest before tests would begin.

Several hours passed and the Brit still hadn’t returned. Johnson called the hotel, and was told the technician had never checked in. Following an unsuccessful manhunt through Hollywood, Johnson checked the missing-persons bureau, where he found his expert in custody.

The man had unsuspectingly jaywalked across Hollywood Boulevard, apparently, and had no draft card or passport or any other form of identification — so the police had no choice but to arrest him. He referred the police to Lockheed, where of course no one knew anything about any British technician or top-secret plane. By that time, Johnson’s expert was in so deep with the law that his release couldn’t be secured — even with the help of the U.S. War Department — until the following morning.

That morning the plane was suspended by belly bands for flutter and vibration tests. Fuel was pumped in and out, and brake tests conducted. The cockpit canopy release mechanism test shook the makeshift tent so forcefully that those present thought the entire structure was about to collapse. And when the crew readied to pull the Lulu Belle out for her maiden voyage, they discovered that because of the way the tent had been hurriedly assembled, the whole thing had to be torn down so the plane could exit.

Finally — on Day No. 139 — the Lulu Belle was secretly trucked out in the dead of night to the California Muroc Restricted Air Base (now Edwards Air Force Base) to run the engine. And the first time the starter button was pressed, the British-designed de Havilland engine roared spectacularly to life.

Notwithstanding previous delays, Johnson now felt more confident than ever that his Skunk Works crew would deliver on time. And just four days later, on November 15, 1943 — Day No.143 — the Army Air Force officially approved and accepted delivery of the promised jet fighter prototype — a full 37 days ahead of the Army’s schedule.

Johnson was especially gratified because his private schedule had always been 150 days. But now the Lulu Belle would need to become the Shooting Star — a pilot-safe, fully operational jet fighter.

Later that evening — during the plane’s final tune-up, with the powerful engine howling at full power — a tremendous bang was heard. Johnson, standing between the two engine ducts to watch the operation closely, almost lost his pants down the intake. Both ducts had collapsed, and before the engine could be turned off, pieces of flying metal were vanishing — with a violent and angry cry — into the engine’s hungry mouth.

Jet engines aren’t designed to digest metal, but perhaps the damage wasn’t too serious — that was the prevailing hope as Johnson and several others violated the Sunday rule, tearing into the engine’s British nuts and bolts with unfamiliar British tools. Disassembly was completed just before dawn, and the Brit peered into the grease-smeared faces of the mechanics, who awaited the expert’s word.

“This crack in the compressor housing — you’d better ask for another engine,” he frowned. “I’m frightfully sorry, but you won’t be able to fly this one.”

This information — and the crew’s disappointment — sunk in all at once. The intake ducts would have to be redesigned and newly fabricated. And Skunks Works could do nothing but wait until another English engine was delivered.

When Johnson was setting up his secret shop, Al Capp had just introduced the “L’il Abner” comic strip, which featured a malodorous moonshine still called the “Skonk Works.” Its connection to the nearby plastic factory’s odor was so obvious that one day one of the engineers wore a gas mask to work as a gag, and a designer answered the phone, “Skonk Works!” Johnson didn’t like the name, but soon it was changed to Skunk Works — and it stuck.

Johnson’s men were granted access on a need-to-know basis. Even the janitors weren’t allowed inside the tent, so the trash piled up — but the work carried on. Johnson could be an impossible boss, often getting so angry that he’d just fire someone — though most knew he usually didn’t mean it. One longtime employee called him “W.C. Fields without the humor,” with a “chili pepper temperament” that was “poison to any bureaucrat, [and] a disaster to ass-coverers, excuse makers and fault-finders.”

Nearly two months elapsed, and now the Shooting Star is aboard an Army truck trailer, surrounded by heavy guard.

It’s just after dawn on Saturday, January 8, 1944, and the plane reaches the Army’s experimental field in the Mojave Desert as a raw wind sweeps across the cold, damp morning. The shivering Skunk Works engineers — bussed to the desert for the test flight — are warming themselves with sagebrush bonfires along the airfield’s north end.

Mechanics engage in last-minute checks while Johnson exhorts his ace test pilot, Milo Burcham, who also flew the P-38 Lightning, among other Johnson designs.

“Just fly her, Milo,” Kelly tells Burcham. “Find out if she’s a lady or a witch. And if you have any trouble at all, bring her back. She’s all yours from here. Treat her nice.”

Burcham climbs in, fastens on a brightly colored football helmet, snaps down the bubble canopy, and starts the engine. A roar booms across the desert. On a knoll above the airfield, the crew straightens to alert. Burcham waves to them.

Burcham taxies, the whine of the engine at full scream, and the jet takes off. The Shooting Star is airborne.

The pilot circles the field, slowly at first, but as the plane gains altitude, it wobbles — and Burcham quickly noses the plane down and turns it around to land. The engineers stand silent as Johnson and a few others rush out to the plane.

“Over-cautious, maybe,” Burcham admits to Johnson. “She felt funny on the ailerons. Pretty touchy.”

“You’ve got 15 to 1 boost and a hot ship that’s naturally sensitive,” Johnson reminds him. “Maybe you were over-controlling?”

“Could be,” Burcham agrees.

While the two talk it over, spectators dig their hands into their pockets, kicking angrily at rain puddles or savagely at sagebrush.

Now Burcham restarts the engine and the plane takes off again, buzzing low across the field and roaring angrily out of sight. When he returns — fast, and from such a great altitude as it dives toward the field — no one even knows it until the plane has already passed overhead and the crowd hears its roar.

“A blast of sound that surrounded us without seeming to originate anywhere,” Johnson called it. “A totally new sensation.”

After an hour of aerial gymnastics, Burcham heads back for a landing — and he’s coming in hot. The pilot tears back the bubble canopy almost before he finishes taxiing, jumps to the ground and throws down his helmet.

“Jee-sus Chee-rist, what a plane!” he shouts.

When properly flown, the Me-262’s superior speed enabled penetration of Allied airspace, and proved difficult to counter-attack. In direct combat, Nazi pilots claimed five or more Allied kills for every Me-262 they lost. And through to the end of WWII, the Me-262 served in a variety of roles — including light bomber, reconnaissance aircraft and experimental night fighter.

Air Force officers had delighted in Burcham’s spirited show — and the Shooting Star’s record-breaking 500 mph-plus speed. They wanted many more jets, and quickly — and Johnson and Skunk Works were ready, willing and able. But delivery would not come without cost.

“Shooting Star” was a misnomer. Lockheed had boasted that its plane, unlike its nemesis Nazi jet fighters, left no telltale comet-like exhaust trail by day or by night. The Army had wanted proof, so Lockheed pilot Ernie Claypool flew one night into a darkened sky and never returned. Flying so clean and devoid of a trailing path, an Army bomber hit it head-on. All occupants of both planes died instantly — and the point was tragically made.

Later, the great Milo Burcham also would die in a crash shortly after takeoff due to failure of the fuel system. An emergency auxiliary system was added as a result, but Major Richard Bong also was killed in a crash when he failed to turn the system on following an engine failure.

Meanwhile, the Me-262s — which had struck such fear into America’s heart — were flying in increasing numbers. But the Allies were effectively countering by attacking the German aircraft while they were still in their hangars, or while taking off and landing. The Allies were beginning, finally, to win the ground war.

In the end — though the Nazis experienced more technical and production difficulties than had originally been forecast — the Allies were lucky that the German jets were not unleashed sooner, or they might have had more than just a negligible impact.

Though World War II ended before the Shooting Star could prove itself in Europe, Lockheed still would build and deliver nearly 9,000 more of them. And the first U.S. jet fighter ultimately would show its mettle in the Korean War, winning the world’s first all-jet dogfight by shooting down a Soviet MiG-15 in the skies above North Korea.

Lockheed allowed Johnson to continue to run his relatively tiny research and development operation as long as he kept it on a shoestring and it didn’t distract from his principal duties. Overhead was kept low, and financial risks to the company stayed small — which was fortunate, since the first two development projects following the Shooting Star were absolute clunkers.

But Johnson — and Skunk Works — more than survived. By the time Johnson retired in 1975, he was responsible for the design of more than 40 wartime and Cold War-era aircraft. And the Lockheed Martin Skunk Works thrives to this day.

Special thanks to Steve Justice, Heather Kelso, and Michigan Engineering alumnus Benjamin Marchionna (BSE AeroE ’11) of Lockheed Martin for making available to The Michigan Engineer materials that had never before been released to the public; to Brook Engebretson of the Huntington Library, where many of Kelly Johnson’s personal papers are now held; and to Johnson’s stepson, John Horrigan, for his availability and cooperation.

During his 42-year career, Johnson contributed to the design and construction of more than 40 aircraft — including the path-breaking F-104 Starfighter, U-2 reconnaissance, SR-71 Blackbird, and F-117 Stealth Fighter.

Though the urgency for the Shooting Star might have been exaggerated, the Nazi threat, coupled with Johnson’s peculiar characteristics — what current Lockheed Martin Skunk Works Vice President Al Romig referred to at the 2014 Michigan Aerospace Centennial weekend as the confluence of “an existential threat and a magical man” — was perhaps the only way such a unique operation might ever have been formed in the first place.

Johnson soon would organize his operational directives into “The 14 Practices and Rules,” and skunk works-style tactics have become the standard by which small, unconventional and autonomous groups might best achieve achieve rapid, innovative and extraordinary results on advanced or secret projects.