The bumpy road to greatness

A rough 2024 season sparks frustration—but also leadership and learning—for the Michigan Baja team.

The four-wheel-drive clutch jammed as mechanical engineering undergraduate David Grover sped into the first sharp turn of the obstacle course at a 2024 Baja SAE International Competition, held at a dusty desert track near Gorman, Calif. in April 2024. Stuck in four-wheel drive, he was unable to drift smoothly through the turn, instead slowing sharply and taking it wide. The car’s poor maneuverability cost valuable time, and every sharp turn after piled on more seconds as four-wheel drive’s limited acceleration and handling sapped performance.

Hobbled by the transmission issue and a clogged gas cap that dampened acceleration, Michigan Baja ended up placing fourth overall. It was a disappointing outcome for a team that has placed among the top 3 Baja SAE International teams for the past 11 years. Their chance of winning the championship, which is determined by their performances at three different competitions throughout the year, was in jeopardy.

The Michigan Baja car sets out on the endurance track in a 2024 Baja SAE international competition near Gorman, Calif.

Afterward, there was nothing to do but head back to Ann Arbor and figure out how to move forward from the latest setback in a bumpy Baja season. But while the 2024 team faced its share of disappointments on the track, every setback was also an opportunity to learn, adapt and improve.

The hardships fueled teamwork, creativity, grit and empathy, which are among the leadership competencies that Michigan Engineering has identified as critical to student success. Michigan Engineering derived the competencies from surveys of faculty, students, employers, research by engineering educators, and recommendations by engineering accreditation organizations, and the College’s experiential learning framework launched in 2022 to help students develop, track, certify, and reflect on the competencies.

Transcript

Linnea: We’re probably one of the most successful teams in the Wilson Center. We’ve won nine out of the past 11 world championships, and we’ve won four straight for the past four years.

Narrator: Every year, University of Michigan students design, manufacture, and test over a thousand parts in a quest to build the perfect all terrain Baja race car.

Linnea: Every year, we’re iterating on our previous design and finding ways to make it better based on like failures we saw during testing or during competition.

Narrator: Then they push their vehicle to the extreme. They test it for speed, toughness, and maneuverability. The suspension system gets its own day in Hell. Same goes for the four-wheel drive.

Grady: As an engineer, I’ve grown so much.

Pablo: It’s just crazy how a year ago, this was the whole car you see right now. It’s just, a bunch of ideas coming from like 20 people.

Linnea: For votes is in this corner.

Margaret: The soft skills is definitely like communication,

“Pablo, did you have anything else?”

Margaret: Time management

“Other than that, no.”

Margaret: Project management.

“Yeah, yeah.”

Linnea: Ultimately, winning is what our goal is and what we strive for every single year.

Narrator: This year, the first competition is in Gorman, California— A historic weigh station, where three mountain ranges meet. Baja SAE California is a four day showdown. It starts with inspections and static events, including business, cost, and design presentations.

Linnea: Good afternoon everyone. My name is Linnea Lindblom. I’m captain of Michigan Baja Racing. That experience on Baja designing components that actually get manufactured is like huge and prepares you for industry significantly better than any class could.

“So at the beginning you talk about acceleration time as a high …”

Rudy: It’s gonna pass. Easy money. We got this. [celebrating]

Narrator: Michigan placed first of the 61 teams after the static events.

Simran: The team is building a car, however, you are only building a certain part of that car. So it’s super important to be able to communicate with everyone else on your team and make sure that your designs are compatible with each other. They are interfacing correctly with each other.

Margaret: Today’s the dynamic day. That means, we have four different, small events that we have to compete in.

Narrator: Dynamic day tests the car’s hillclimbing, maneuverability, suspension and acceleration.

Our four wheel is not disengaging very well.” So we’re going to put a different driver in and see if they can muscle through it.”

Linnea: I’ve I think always kind of thought of engineering as you have a problem and you’re going to figure out how to solve it. And I think that’s ultimately what Baja is. How are we going to solve this problem that we have? Yeah, we started with hill climb. And yeah, had issues from the beginning with four-wheel drive.

Margaret: Either they can’t engage it or they can’t disengage it. Because when we’re in four-wheel drive we’re slower. So we want to be able to switch into two-wheel drive quicker.

Linnea: Was able to make it work. Was able to complete it. And then yeah I just spent most of the mid afternoon just trying to solve four wheel drive issues before maneuverability.

“Hold on. Out. In. Out. In.”

You know, there’s always stuff that you don’t expect to happen.

“Try and lock his brake, like…”

…That you don’t really foresee. But it’s hard. And it’s, you know, frustrating sometimes.

We’re still having problems with the car shifting in and out of four wheel drive.

Margaret: For maneuverability. We took 11th. We’re currently 11th place.

Simran: Being that we are very heavily a design-based team, creativity is pretty huge for design. Making sure everything can integrate together. Everything works together is huge. However, we don’t … we don’t spend as much time on it as we probably should, which is a lot of the reasons why we run into all these issues when we’re trying to put the car together and things don’t fit well.

Narrator: Michigan comes in 17th at the hill climb and 12th in maneuverability.

Pablo: Each four corner needs adjustments. So we’re gonna do that real quick, go do a practice check and they go…

Narrator: The team needs to do well at the suspension event to keep its chances of winning in California alive.

“No. Go go go go go go go go. Let’s go go. Go go let’s go, let’s go.”

“Thirty seconds ahead. We’re first.”

“We’re in first right now.”

We just did our first round of the suspension interaction event. We’re able to finish. And we’re one of the I think four cars. So total, that finished it which is awesome. I’m super, super happy. We needed this really, really bad. This is a good mood booster that it’ll help us carry this into tomorrow. And, Yeah, we’re very excited. now. We’re back. We’re so back.

Simran: Teamwork is the biggest thing when it comes to Baja, because you can’t build a car on your own in a year especially. That’s physically impossible. I think that’s very important. Learning how everyone has a place in the team and everyone has a specific job. Everyone’s the best at that specific job. And without it, we’re not going to be as good as we could be.

Margaret: Based off of excel, yesterday, we got placed in second. So our starting lineup is we’re going to start behind the first place.

Pablo: Endurance. This is 40% of the points. So it’s very important to stay on track the whole race. You stay on track. Your chances of winning shoot up very high.

Linnea: So we have four hours of wheel to wheel racing. Usually we’re on track for almost all four hours. We don’t have any component failure, so hopefully we’ll be able to repeat that.

Simran: Definitely it takes great resilience to be able to get through all the issues that just come with trying to build a car, especially like we are college students, so we don’t know everything there is. So just being able to stick with it and running through those problems work together as a team to solve it and get past it definitely requires a huge amount of resilience.

Ian: The car’s going a bit slow, and we’re not sure if the engine is bogging down. We’re not sure what’s up with that.

“Michigan, you’re …”

“I’m just checking everything on the corners.”

Margaret: We’re not completely sure what’s wrong with it. So we checked a few things and we check the CVT. That looks fine, so we replace the carburetor. Hopefully that was the problem. And then. Yeah, we check gear box stuff.

“Do we fuel while we’re here?”

Margaret: We’re some laps behind now. Hopefully we’ll be able to make it up. We still have majority of the race left, but it did take a little bit of a hit by having to take it out for as long as we did.

We’re about seven laps, behind first place right now. We had some issues, with the engine. We are probably still having those issues, so I don’t. I don’t know if we’re making up time, but fingers crossed.

Ryan: So, our, our rear brake went way early in the race, and that was okay. We can still stop the front brakes. Now, if sounds like our front brakes are starting to lock up. We’re having trouble with our, like, brakes, not disengaging. So losing a lot of power for that.

“It’s possible, he was on the brakes pretty hard. Like you can hear it from a good distance away.”

“That was the rear.”

Ian: Essentially the front brake rotor. We’re not sure how, but it got bent, and it destroyed the front caliper and broke a hole in it. So we lost all of our brake fluid. So we pretty much had no brakes. So we had to swap the whole front hub of the front caliper and also replace the rear line. The rear brake line.

“In a crisscross pattern. Alright. Go, go, go. Who’s pushing? Push.”

Narrator: The University of Michigan Baja team finishes the overall competition in fourth.

Pablo: I guess it was just the most frustrating part was knowing this car could do a lot better. But I learned a lot this year. I think the main point that I’ve learned is test things as much as possible. Driving time before competition is extremely valuable here. We could have caught things beforehand if we had more driving time. I really value my time on Baja, just because I’ve got to meet people, make friends. I’ve gotten to actually apply what I learned on a physical opponent. Can’t imagine what I’d be like not on the team. So yeah.

David: I think you learn a lot more from failure than you do from success. That’s kind of why we have behind here in the cage a wall of all of our broken parts. As a reminder, like, hey, we you know, we’ve had a lot of hard times and that’s what’s made us so competitive, so resilient, so knowledgeable. And that is super helpful for not only, you know, the team this year, but all future teams.

For most students, the best way to hone these skills is with hands-on experience. The Wilson Student Team Project Center provides that experience, with 30 student teams housed in a well-equipped makerspace. The experience sparks innovation, camaraderie and experiential learning as students work day and night to build machines like off-road vehicles, solar cars, rockets, Mars rovers and electric boats. The projects inspire lifelong learning [leadership competencies] that keeps many students coming back year after year.

“I thought it was amazing that you could go from knowing absolutely nothing to being able to fully build a car,” said mechanical engineering junior Simran Bagri, recalling her very first Baja meeting. “And so I stuck around.”

A major challenge in Michigan Baja’s 2024 season was honing its shift-on-the-fly four-wheel-drive system. The design inherited from previous years required an inordinate amount of muscle to switch between two- and four-wheel drive at high speed. The issue hadn’t stopped previous teams from placing in the top three, but the team felt that the competitions were growing too close for comfort.

“We won by a hair last year . . . and going into 2024, we felt that was very reflective of the fact that our car had stayed the same for so long,” said Grover, who was the rear gearbox lead for the 2024 car. “We needed to make the car more capable.”

They hatched a plan to switch from a “dog” clutch that engages interlocking teeth to a friction plate system that would enable easier shifting. It was a risky step because the team had little experience with the new system.

“I knew every time we had to do something new there was a risk, but I’d rather take that risk [leadership competencies] than stay stagnant,” said Pablo Elizondo Del Bosque, mechanical engineering junior and a continuously variable transmission lead. “If you copy and paste parts from last year’s car, that’s not going to make you an engineer.”

The team hedged their bets by producing two clutches—both a new friction style and a revamped version of the previous dog clutch.

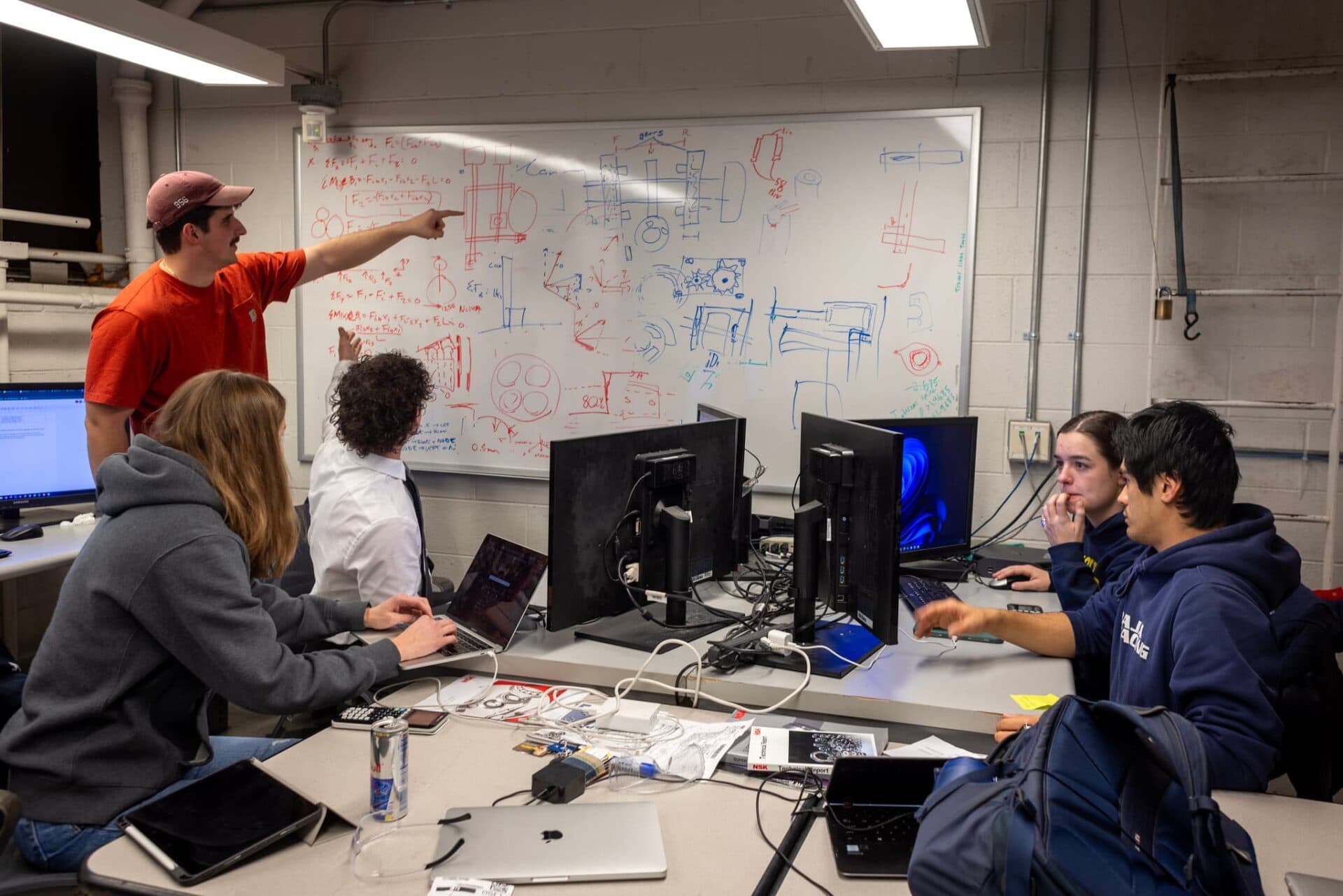

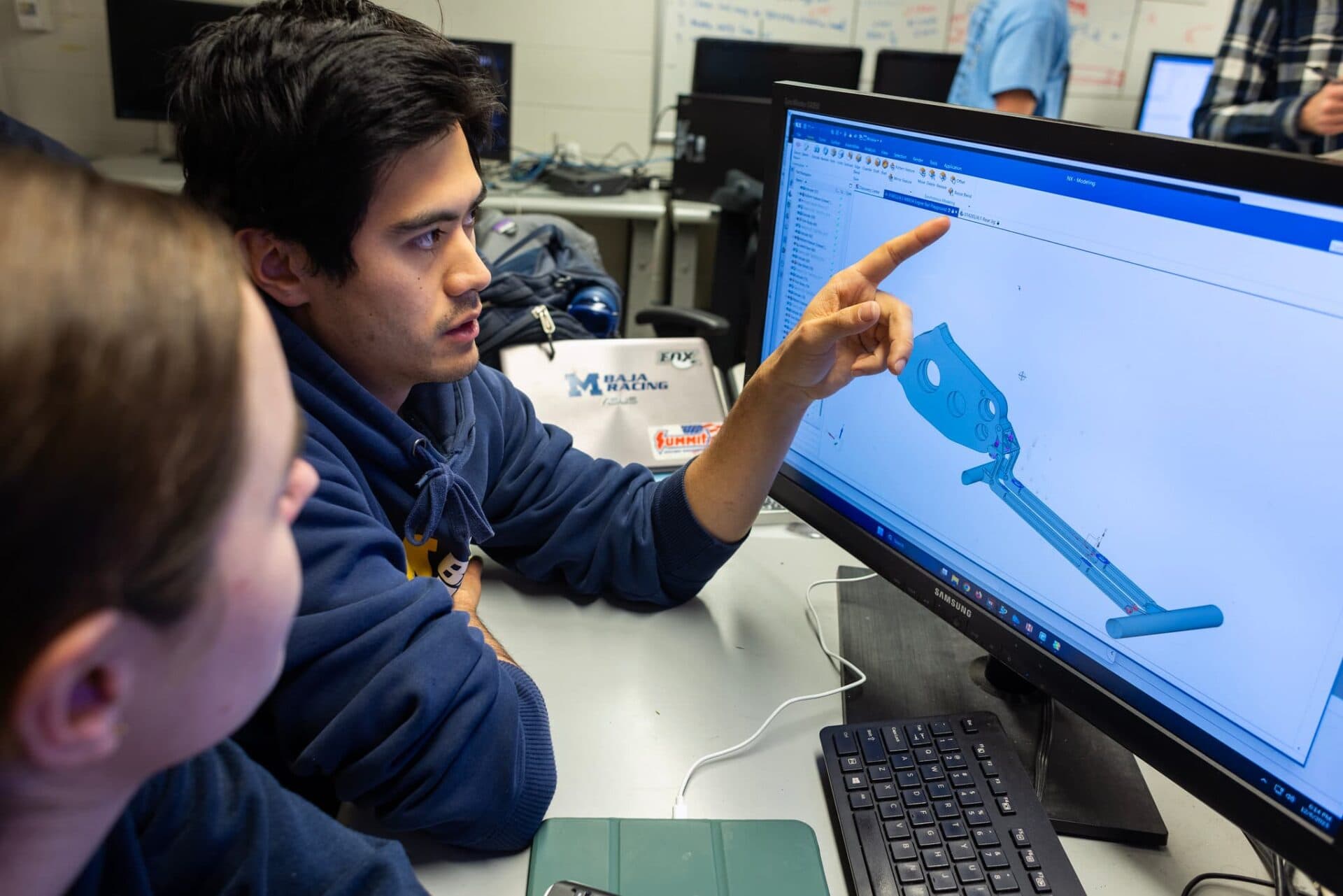

Design and production of the 2024 car began in August 2023 at the Wilson Center. The team used computer-aided design to optimize each part based on designs of previous Michigan Baja cars. An exercise in systems thinking, [leadership competencies] the process required subteams to work together to integrate each subsystem into a cohesive finished product.

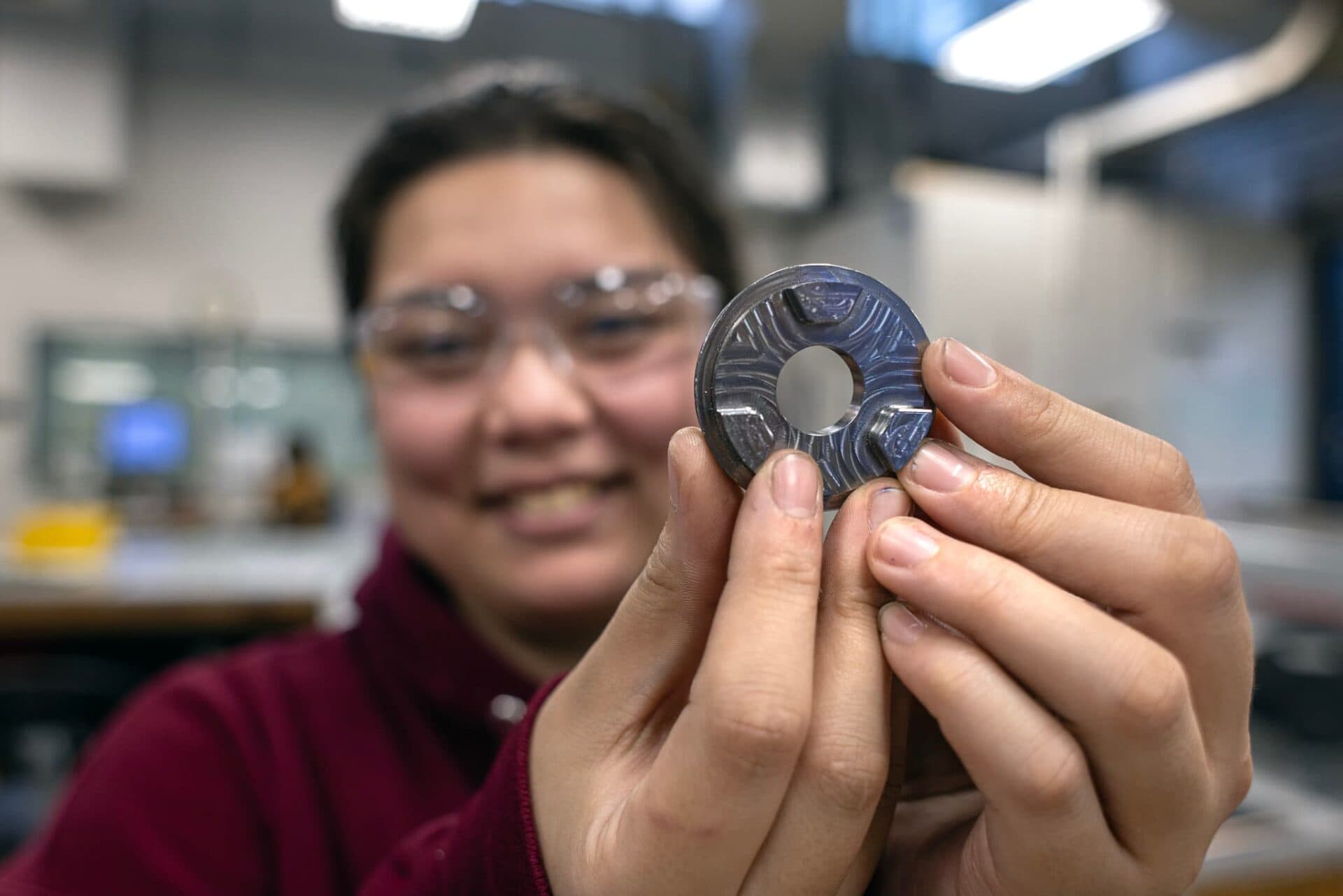

In October, the team headed to the machine shop, where robotics junior and in-house manufacturing director Margaret Kempe led the production process. They manufactured 90% of the car—about 1,000 individual parts—on the Wilson Center’s mills and lathes.

The Baja team made 90% of the car–around 1,000 individual parts–at the Wilson Center.

To build a car in time for the competition, the team not only needed to design for performance, but also for feasible manufacturing. To make it happen, the team’s design and manufacturing teams communicated [leadership competencies] closely throughout the process.

“As a machinist, I don’t necessarily know the design that’s going to happen. Likewise, the designer doesn’t necessarily know the capabilities of a machine, so it’s just a balance of two different knowledge skills to actually produce something,” Kempe said.

Production was finished in March 2024, but the friction clutch wasn’t working as planned. With time running short, Grover and the team made the call to swap in the revamped dog clutch.

Another setback came a few weeks later, when a steep climb sheared one of the car’s front axles in half just minutes into a test drive. The team had to call off the test and head back to the shop to begin work on a replacement. This curtailed any further testing of the new four-wheel drive system, with the California competition only two weeks away.

Bagri explained that when deadlines grow tight, empathy [leadership competencies] helped the team stay focused

“To be successful as a team, you need to understand that people sometimes fall behind,” said Bagri, who was also the team’s external manufacturing director. “Rather than make them feel bad about it, you need to work with them to catch them back up.”

Back at the Wilson Center, mechanical engineering senior Ian Beaufait led the subteam that quickly designed and manufactured a beefed-up axle. But there was a wrinkle: Axles require heat treating to improve their strength, and heat treating requires an outside supplier.

While the axle was being treated, the car’s four-wheel drive system was out of commission, making testing and refining the system impossible. During stressful times like this one, Kempe said the team tended to draw on Lindblom’s leadership [leadership competencies] skills, technical prowess and calm, cool demeanor.

“Linnea is a really powerful captain in the sense that she’s super-confident in everything she says and does,” said Kempe. “Everyone trusts that she knows what to do. When Linnea speaks, I know that we are going to have a car in time for the competition.”

The shifting issues cost the team dearly in the California competition. Afterward, the team discovered that the gears in their clutch were binding too tightly because of the position of their shift fork—a metal lever that slides gears together to engage four-wheel drive. They were able to modify the fork to get their four-wheel drive system shifting smoothly for their next competition in Williamsport, Pa., two weeks after the California race.

But the four-wheel-drive issues left the team with less time to test the car’s other subsystems, a problem that proved disastrous in the rough track conditions of the Pennsylvania race. The car’s suspension failed three times, and every attempt at repairs made matters worse. Any hope of a 2024 championship was lost in Pennsylvania.

The team tests the car–and its drivers–at their test track in Ann Arbor.

The team was disappointed by their performance in Pennsylvania, and not just because of the pressure to maintain a winning streak. Grover explained that simply getting a finished car to competition was a herculean effort, to which many of the students devoted most of their waking hours. But every setback was also an opportunity to learn, adapt and improve.

“You don’t learn anything from doing well . . . so I think having this experience will make us even stronger,” Grover said.

The team used the lessons learned from Pennsylvania to improve the car’s suspension for the final Baja SAE International competition in Holly, Mich., which took place between September 12 and 15. The hard lessons from California and Pennsylvania paid off, and the team was able to finish the Michigan competition’s endurance race without being towed off the track for repairs—a first for this season. The team placed 8th in the race, and 4th overall in both the Michigan competition and the entire year.

Learning how to extract value from failure and gain the grit [leadership competencies] required to solve tough problems is an important skill for an engineer, said Jeff Walker (BS ME ‘10). Walker was the Baja team captain in 2009 and is now the engineering manager for crate engines and performance parts at General Motors’ Milford Proving Grounds. Fourteen years later, he still draws from the lessons he learned with Baja.

“You learn the customer base, how to talk with suppliers and design for feasible manufacturing. I learned all that stuff in the Wilson Center,” he said.

“Engineers are full of ideas, but when you get in the real world, not all those ideas come to fruition. Something happens and you have to rework the idea. How you react to that situation is really important. Do you shut down, or do you continue to work at it and make something better next time?”

Defining leadership competencies

Michigan Engineering’s student teams are one of the many ways that engineering students can hone the following leadership competencies:

Communication

Ability to critically read, listen, reflect, and convey information effectively in a variety of media with diverse audiences across a variety of settings and contexts.

- Article Reference:

To build a car in time for the competition, the team not only needed to design for performance, but also for feasible manufacturing. To make it happen, the team’s design and manufacturing teams communicated closely throughout the process.

See in article

Creativity

Ability to generate ideas, processes, products that are both novel and appropriate.

Empathy

Ability to understand, appreciate, value the perspective of someone else by reasoning from their premises, assumptions, or ideas.

- Article Reference:

Bagri explained that when deadlines grow tight, empathy helped the team stay focused

“To be successful as a team, you need to understand that people sometimes fall behind,” said Bagri, who was also the team’s external manufacturing director. “Rather than make them feel bad about it, you need to work with them to catch them back up.”

See in article

Entrepreneurial Mindset

Ability and intent to engage proactive, innovative strategies in various contexts to solve ambiguous problems.

Ethics

Fully engage stakeholders to recognize that actions and choices have consequences, and that one must act with integrity and trustworthiness.

Global and Cultural Awareness

Ability to acknowledge, practice, and articulate one’s own cultural identity to better appreciate, adapt to, and interact with individuals from differing backgrounds, values, and cultures.

Grit

Ability to persevere and maintain commitment for achievement of long-term goals, despite setbacks, failure, and/or adversity.

- Article Reference:

Learning how to extract value from failure and gain the grit required to solve tough problems is an important skill for an engineer, said Jeff Walker (BS ME ‘10). Walker was the Baja team captain in 2009 and is now the engineering manager for crate engines and performance parts at General Motors’ Milford Proving Grounds. Fourteen years later, he still draws from the lessons he learned with Baja.

See in article

Leadership

Cultivating an environment that collectively develops a shared purpose and inspiring others to work toward it.

- Article Reference:

While the axle was being treated, the car’s four-wheel drive system was out of commission, making testing and refining the system impossible. During stressful times like this one, Kempe said the team tended to draw on Lindblom’s leadership skills, technical prowess and calm, cool demeanor.

See in article

Lifelong Learning

Ongoing desire and fundamental ability to recognize personal skills and knowledge deficits; seek out and acquire needed skills and knowledge; and continue to grow new interests, talents, and passions.

- Article Reference:

“The experience sparks innovation, camaraderie and experiential learning as students work day and night to build machines like off-road vehicles, solar cars, rockets, Mars rovers and electric boats. The projects inspire lifelong learning that keeps many students coming back year after year.”

See in article

Risk Taking

Ability to critically assess available information, take action despite uncertainty, manage outcomes, and learn from failure as well as from success.

- Article Reference:

“I knew every time we had to do something new there was a risk, but I’d rather take that risk than stay stagnant,” said Pablo Elizondo Del Bosque, mechanical engineering junior and a continuously variable transmission lead. “If you copy and paste parts from last year’s car, that’s not going to make you an engineer.”

See in article

Systems Thinking

Ability to recognize and appreciate the complex structures and their interconnectedness which are embedded in a system while maintaining a view of the highest level objective to be achieved.

- Article Reference:

…Design and production of the 2024 car began in August 2023 at the Wilson Center. The team used computer-aided design to optimize each part based on designs of previous Michigan Baja cars. An exercise in systems thinking, the process required subteams to work together to integrate each subsystem into a cohesive finished product.

See in article

Teamwork

Working to define and achieve a shared goal by leveraging individuals with different perspectives, roles, responsibilities, and aptitudes.

Michigan Engineering offers a digital tool for its students, called Spire, to track, certify, and reflect on their development of these competencies. For more information on experiential learning at Michigan Engineering, visit the associate dean for undergraduate research website.